Trust, Biosecurity Underpin 30-Year-Old Thai Egg Business

Visitors to the C&C Eggland Company located in Korjan in the Chonburi province of Thailand, cannot fail to be impressed by the level of biosecurity that the company insists upon, reports Stuart Lumb.

The farm is completely surrounded by a large fence and visitors on arrival have to walk through a spray race, after which they are then sprayed all over with disinfectant by a member of the farm staff.

The “C&C” in the company name, in fact, refers to two generations of the Intanurangsi family and an egg motif features prominently in the company logo. The layer business was set up in 1984 although the family was trading eggs before that.

The farm buildings are spaced well apart and recently a new facility has been built. This facility houses the office staff and a large seminar room which is used to entertain visitors and doubles as a staff training facility.

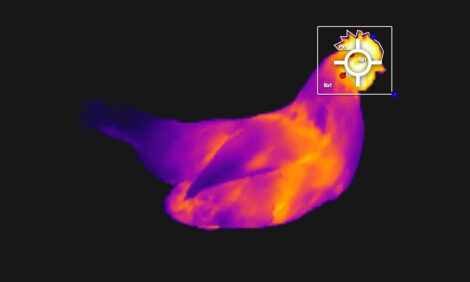

Layers were originally housed in traditional open buildings. Then, in 1997, the business invested in closed buildings which were imported from Spain as a turn-key package with Spanish specialists overseeing the erection and commissioning of the new layer accommodation.

Ten years later, in 2007, equipment was purchased from Big Dutchman and more recently, more has been imported from Italian company, Valli S.p.A.

The houses have four tiers of cages accommodating 42,000 birds, with each bird having a space allowance of 450 square centimetres. This number of layers is considered the ideal number that one member of the farm staff can satisfactorily look after. There are 100 staff working in teams, on the farm.

Training is provided in-house. The farm staff all live in company accommodation on the facility, a situation commonly found in Asia. Consequently, no travelling is involved for the farm staff plus having them all living on site is a big bonus as far as biosecurity is concerned.

Seedstock used to be sourced from Apex but Hy-Line is now preferred. Members of the family travelled to Des Moines in Iowa, US to meet up with the Hyline management staff. Eggland was impressed with the company, which explains the change in genetics.

Corn is the major energy source as far as feed is concerned, with feed being stored in a number of glassfibre bins. Interestingly, no extra vitamin A is added to the feed as yolk colour is something that is not a concern for Thai consumers.

An adequate water supply is always a major priority in hot climates. Often farms have their own bore-holes providing water but Eggland relies on rainwater, which is collected in a large reservoir. Water quality is checked monthly for E. coli and Salmonella.

The farm naturally produces a considerable amount of manure. Interestingly this is not used as a fertiliser but is sold to fish farmers who use the manure to inoculate their ponds when starting up tilapia production. The manure – a natural fertiliser – stimulates the growth of phytoplankton which is a source of feed for the tilapia.

Far-sighted farmers some years ago took their business “beyond the farm gate”, to take the middleman’s profit in order to ensure that their business remained viable, this being the reason for the establishment of farmer’s markets in the UK, for example.

However, Eggland have always traded eggs and so is a totally integrated business, not just producing the eggs but also selling them directly to the consumer.

Overall production averages around 300,000 per day and the eggs, which are graded into seven categories, are transported in trays.

Eggs are not packaged as Eggland does not sell to the supermarkets. Eggs are shipped as far as 700km from the farm to a network of traders and shops in a sales operation that is based on trust and has been built up over many years.

October 2014