What protein level will maximise your profits

By Marcus Kenny, Carolyne Kemp and Colin Fisher, Aviagen - This article by Aviagen explains the need for varying dietary protein in order to maximise profits in a broiler operation.

Aviagen publish nutrient

density recommendations for diets

fed to broilers in the starter, grower

& finisher period (Table 1), with the

comment that the nutrient levels

need to be adjusted to maximise

profitability under local conditions.

It is now widely accepted that the

choice of dietary protein level is an

economic decision to be made for

each company or enterprise. This

idea replaces the concept that birds

have characteristic ‘requirements’

which should be met under all

conditions.

The effect of dietary protein level on biological performance

Results from a recent Aviagen

trial demonstrated the effect of

increasing protein levels in the diet

on Ross 308 male growth and FCR

to 41 days of age and were

consistent with previous trials and

field experience. The control

treatment was formulated to meet

the current Ross 308

recommendations while the protein

level in the trial treatment was

formulated to achieve 85% of the

control diet level.

In this article, protein refers to

available amino acids and all trial

diets were designed to provide

different levels of balanced protein

using the ideal amino acid profile as

per the recommendations published

in the Ross Broiler Manual (2002).

It can be clearly seen from Figure

1 that bodyweight and FCR improve

significantly as protein levels are

increased. A lower dietary protein

also affects white (breast) and dark

(leg) meat yield. This effect is shown

in Figure 2.

However, a lower protein level in

the diet will be a cheaper

formulation, so the effect on the

overall financial performance of the

flock needs to be assessed. Table 2

shows the margin per bird after feed

cost for each diet. Although feed

price has been reduced on the lower

(85%) protein diet the margin is

significantly reduced. Even in a

situation where feed prices increase

by 10%, the reduced protein

treatment results in a lower margin

than the control diet.

The balanced protein calculator

The example above demonstrates

the impact of two very different

levels of protein but does not

indicate what level of protein

optimises margin. To identify this,

Aviagen have developed the

Balanced Protein Calculator. This

calculator is a tool which combines

feed and revenue prices with broiler

biological response data to establish

the dietary amino acid level that

maximises profit for different

objectives e.g. farm versus

eviscerated carcase margin. The

biological response data is derived

from a compilation of Aviagen

amino acid response trials.

The calculation of an optimum

balanced protein level involves

several inputs (Figure 3) Feed cost

at different protein levels is

determined by conventional leastcost

feed formulation based on

relevant raw material costs. Costs of

broiler rearing and processing are

also used. Broiler performance at

each protein level is then

determined from response curves

established from trial data and the

revenue from different types of end

product and costs are identified.

These elements are then combined

to calculate the profit for each level

of balanced protein.

Biological response data

The most important part of the Balanced Protein Calculator is the set of biological response data. The data has been obtained by evaluating the amino acid response of the Ross 308 broiler in an ongoing series of trials between 2002 and 2004. In total 72 responses have been identified.

Calculating bird response

To combine the data from different trials all data were expressed relative to this treatment for the definition of bird response to protein. Slaughter weights of 1.7kg, 2.0kg. 2.5kg and 3.0kg for males and females separately were considered in the analysis.

Calculating costs, revenue and optimum amino acid level for an enterprise

Feed costs were calculated for

protein levels of 70% to 130% of

the Ross manual recommendation.

Other costs such as chick cost and

processing costs were also taken

into consideration.

The calculation of profit requires

data for the various sources of

income accruing to the enterprise;

the value of live birds (per kg), of

eviscerated carcass (per kg) and of

portions.

Calculating the optimum amino acid level

The output from the calculation is

a plot of profit against relative

protein level and an example of

farm growing margin is shown in

Figure 4.

In the example, feed cost data

were based on ingredient prices in

Asia for the range of dietary protein

levels. Revenues were estimated at

0.75 USD per kg live weight, 1.25

USD per kg eviscerated carcass,

1.80 USD per kg breast meat and

2.05 USD per kg for leg meat.

Estimated costs for chicks, broiler

grower overheads and processing

were constant for all protein levels.

The optimum amino acid level for

maximum profit can also be

calculated for eviscerated carcass

and processed portions. Table 3

summarises this data for males,

females and as hatched birds grown

to 3kg.

The optimal amino acid density

for as hatched farm margin is 96%

of the current Ross manual

recommendations but for as

hatched, portioned birds optimum

margin is achieved at 106% amino

acid density. As you would expect,

the level of dietary protein most

profitable, increases as additional

sources of revenue are brought into

consideration.

The responsiveness of the Ross

broiler to increased amino acids

explains why the optimal amino

acid density for portions products is

higher than that for farm margin.

An additional factor influencing

this economic response is the high

liveability of the Ross broiler. The

Aviagen pedigree selection process

has minimised the incidence of

metabolic related diseases even at

high growth rates, hence feeding

higher levels of nutrients to the

Ross bird will not compromise

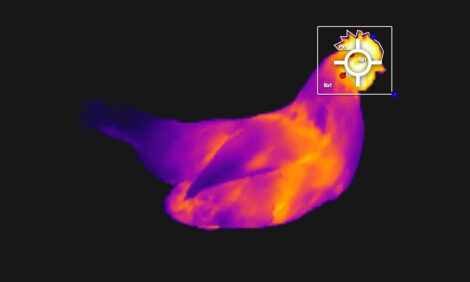

liveability. Figure 5 below shows the

liveability of Ross as hatched birds

to increasing levels of protein and

demonstrates that feeding the Ross

bird for optimal performance does

not compromise the welfare of the

bird.

The cost of optimal amino acid density on financial performance

Using the Balanced Protein

Calculator, can therefore provide

information on the level of dietary

amino acids most

appropriate to

meet the

production

objectives of the

organisation

As can be seen

from Table 4, the

difference in

margin can be significant especially

for an operation portioning product.

For an operation producing 1

million broilers per week,

profitability can be considerably

enhanced by increasing dietary

protein levels to 106% of those

recommended in the Ross manual

as seen in table 5.

Using the Balanced Protein

Calculator, can therefore provide

information on the level of dietary

amino acids most

appropriate to

meet the

production

objectives of the

organisation

As can be seen

from Table 4, the

difference in

margin can be significant especially

for an operation portioning product.

For an operation producing 1

million broilers per week,

profitability can be considerably

enhanced by increasing dietary

protein levels to 106% of those

recommended in the Ross manual

as seen in table 5.

Summary

The optimal amino acid density depends on the objectives of the organisation.

Aviagen have collated a unique set of biological response data showing how the Ross broiler responds to inputs of balanced amino acids.

The Balanced Protein Calculator combines biological response data with feed and revenue prices to identify the optimal dietary amino acid level to maximise farm, eviscerated and portions margin.

Maximum farm margin will be achieved at current Ross recommendations.

Maximum margins in companies deboning a large proportion of product will be achieved when higher levels of dietary amino acids are fed.

The excellent liveability of the Ross broiler allows profitability to be maximised without compromising welfare.