SmartTray: Driving Performance, Uniformity in the Hatchery

SOUTH AFRICA - “It’s quality that counts!” Midway Chickens’ Lee McGrath was very certain of what he expected for his hatchery, when he placed his first order for Pas Reform’s antimicrobial Smart setter trays in Bela Bela, South Africa, a year ago.

Today, as he receives two containers of Microban® treated SmartTray™’s, his view has not changed. After Midway, others followed. From Opti Chicks in Lichtenburg and Supreme Poultry in Bloemfontein, to Eagle’s Pride in Pretoria and Rainbow in Worcester.

Since its introduction in 2008, SmartTray’s success in South Africa has been repeated around the world. Some resourceful customers and their partners have even re-purposed SmartTray for the transfer of hatching eggs to the hatchery, while customers of other equipment manufacturers are also seeing the benefits of using Pas Reform’s setter trays in their equipment.

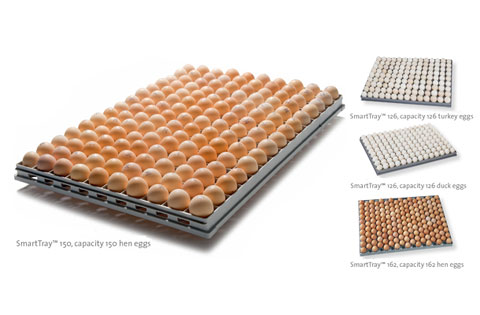

Designed to cradle hatching eggs of any size safely, the open construction of Pas Reform’s SmartTray delivers uniform airflow during incubation. This helps to create an ideal environment for each embryo, to produce day-old chicks, ducklings or turkey poults of the highest quality.

Improved setter tray design delivers greater comfort and uniform airflow

Genetic selection for high post-natal growth has produced higher levels of metabolic heat production by modern chick embryos. This additional heat makes greater demands of setter management in order to achieve optimum hatching results.

Pas Reform’s SmartTray has been designed to help nurture modern embryos during the critical phase of incubation. An open, spacious grid prevents the development of ‘dead spots’, allowing air to flow freely for the homogeneous distribution of heat and humidity.

With integral supports for hatching eggs at two levels, the tray is suitable for eggs of all sizes, with stable, self-centering egg positioning to protect the eggs, prevent hairline cracks – and promote pinpoint accuracy when injecting the eggs during in-ovo vaccination.

The incorporation of Microban antibacterial protection means that using SmartTray actively reduces the risk of cross contamination by food poisoning bacteria, in the hatchery or in the farm, by up to 99.9%.

Safe and secure in handling, stacking and storage

SmartTray was designed to withstand the demands of the highly automated hatchery, from frequent washing and disinfection, to transport, load, impact and temperature changes.

A blind find bottom design finds its own secure locking position for fast, stable stacking, and with a completely smooth finish for easy, thorough cleaning, this HACCP compliant, ergonomically designed setter tray is still lightweight, comfortable and secure in handling.

For detailed information and SmartTray technical specifications, click here.