Spring cool cell start up

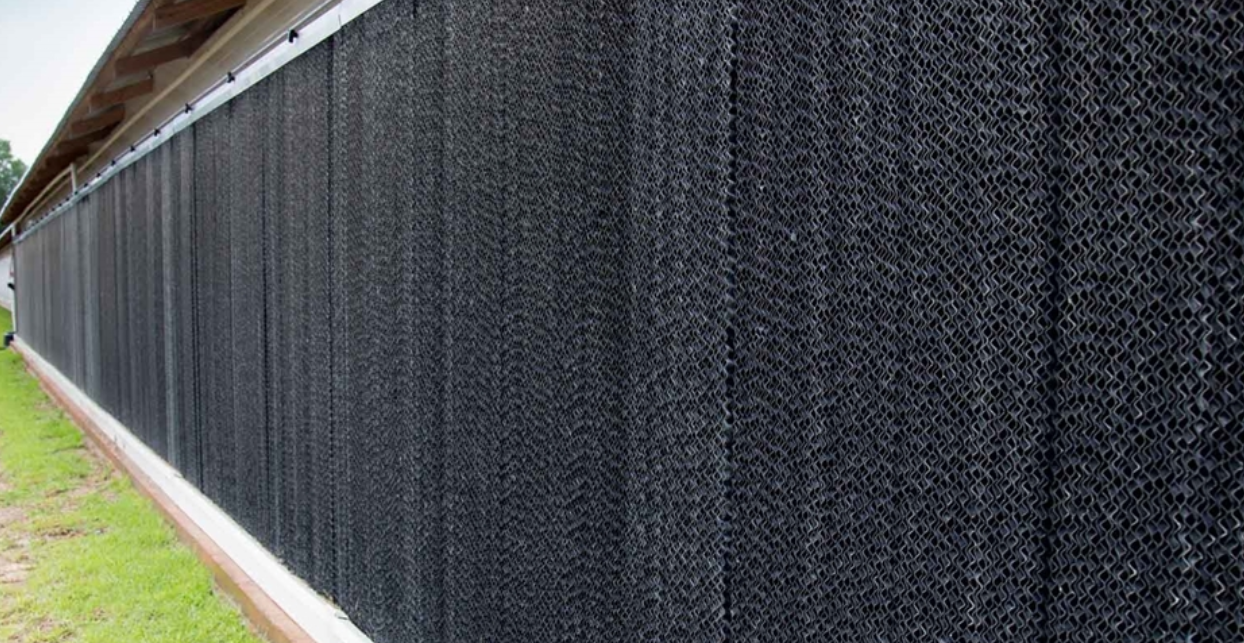

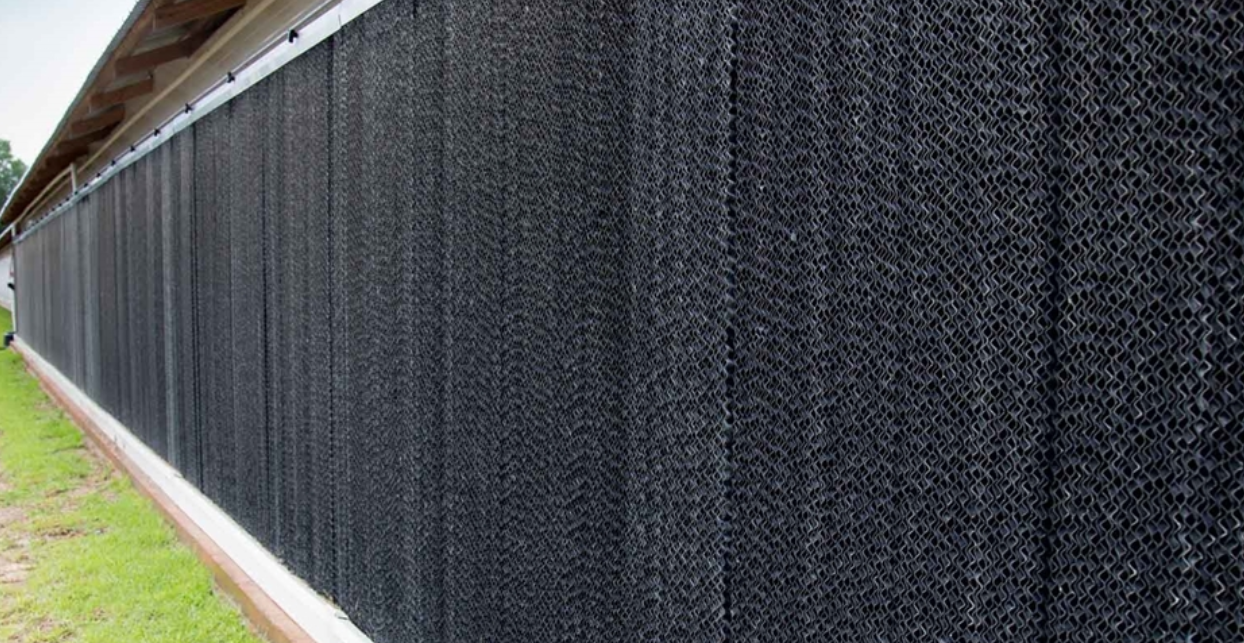

While fans generally get the blame for poor summer ventilation performance, in some cases, it is the evaporative system on the other end of the building that is the culprit. Dirty pad openings can restrict airflow, and uneven water distribution causes streaking resulting in inconsistent cooling. The right procedures at spring startup can prevent problems later this summer.

Start with a clean slate.

Over the winter, insects, dirt, and dust have probably collected on the pad clogging up the flues. Using a high-pressure sprayer will cause damage to the pads. Instead, use a low-pressure hose-end sprayer to flush away debris along with a soft-bristled brush for any heavy accumulations. Do not use bleach or other chlorine-based cleaners that will destroy the pad material.

Check pads for physical damage from rodents and insects. Look for soft areas along the bottom of the pads that can cause the pads to sag. Sagging pads reduce the amount of cooled air entering the buildings by allowing it to "short-circuit" through gaps instead of passing through the pads.

Check the troughs.

Take a few of the pads out and remove any sand or dirt buildups from the bottoms of the trough. Inspect the areas where the troughs join together for gaps or missing caulk. Check for trough supports that might have come loose from the wall.

Start the pump.

Remove the sump or jet pump from winter storage (because you didn't leave it in the tank all winter) and clean out any debris from the strainer basket and body pump head. Open the filter body and clean the screen inside before installing the pump unit on the supply plumbing.

Fill the system with clean water while adjusting the float to set the water level to about one inch below the pad bottoms. Pad bottoms continuously sitting in the water eventually become soft, causing the pad to sag. Check the float after the pad runs for several days to make any necessary adjustments.

Check for streaks and leaks.

Go to the opposite end of the spray bar and open the ball valve, turn the pumps on and flush water out the end until it runs clear. It is an excellent idea to mechanically scrub the inside of the pipe with a bottlebrush attached to a long PVC pipe. You could also purchase a specialty Clean-out Brush with a slip coupling that glues on to a three quarter inch PVC pipe. Run the brush through the spray bar and turn the pump on to flush the system a second time.

Look for streaks on the pad, indicating a plugged hole on the spray bar. Dry or streaked pads at the end opposite the pumps are a telltale sign of a blockage in the system reducing water flow. Now is also a good time to look under the bottom trough for any leaks.

Be prepared for trouble.

Finally, be prepared to address issues that occurred in previous years. For example, if excess algae bothered your system last year, purchase the correct chemical treatment and have it on hand. Start the recommended application before you see a buildup and stay ahead of the problem.

Don't let a poor performing evaporative cooling system limit the effectiveness of your ventilation system this summer by it getting off to a good start this spring.