US Poultry Industry Manual - Broilers: housing and facilities

Part of Series:

< Previous Article in Series Next Article in Series >

Editor's Note: The following content is an excerpt from Poultry Industry Manual: The Foreign Animal Disease Preparedness and Response Plan (FAD PReP)/National Animal Health Emergency Management System (NAHEMS) Guidelines which is designed to provide a framework for dealing with an animal health emergency in the United States. Additional content from the manual will be provided as an article series.

Enclosed housing is standard for the broiler industry and limits exposure to disease-carrying wild birds and animals. Houses should provide a source of heat for brooding and ventilation to supply oxygen and remove carbon dioxide, moisture, and ammonia. Houses should protect chickens from predators and exclude rodents and other harmful pests, such as litter beetles. The footing of a chicken house forms a solid barrier around the base of the house and prevents wood rot, sagging roofs and entry of pests and other intruders. Insulation is placed under the roof and occasionally on side and end walls to help retain heat during winter and exclude radiant heat in summer. Houses with solid side walls have air inlets located down the sides that allow fresh air to enter houses when an exhaust fan pulls air from the house.

Broiler houses typically measure 43’x 500’ and are constructed from metal, wood, or a combination of the two. However, house size ranges from 30’ to 66’ wide and 300’ to 600’ long. Steel truss houses are more efficient and have fewer rodent problems, allow for quicker construction and have better longevity. Wood truss houses tend to be less expensive to build and, when properly designed with a drop ceiling, provide efficient tunnel ventilation and heating. Floors consist of concrete or compacted soil.

Stocking Density

Correct stocking density is necessary to obtain optimal broiler performance, uniformity, product quality, and meet welfare requirements. Stocking density is influenced by climate (temperate vs. subtropical), season, (summer vs. winter), housing type (open-sided vs. solid-wall), target broiler weight at processing, and local welfare regulations. In winter, additional broilers may be placed in a house because heat produced by extra birds is more easily removed with colder outside temperatures. A guide to stocking densities according to bird numbers and live weight is given below from the Arbor Acres Broiler Management Guide (2010).

Table 6. Stocking Densities According to Bird Numbers and Live Weight |

|||

Bird Live Weight (lb) |

Square Feet/Bird |

Birds/ft2 |

Bird Weight (lb/ft2) |

3.0 |

0.50 |

2.0 |

5.99 |

4.0 |

0.70 |

1.4 |

5.73 |

5.0 |

0.85 |

1.2 |

5.91 |

6.0 |

0.90 |

1.1 |

6.70 |

7.0 |

1.00 |

1.0 |

7.04 |

8.0 |

1.15 |

0.9 |

6.99 |

Maintaining normal stocking density is vital for a healthy flock. If overcrowding occurs, body weight suffers as well as feed consumption and efficiency. In addition, mortality can increase along with condemnations. In brief, the negative financial impact of overcrowding is tremendous. In 2012, average stocking density of broiler flocks was 0.84 ft2 /chicken placed or 7.4 lb/ft2.

Feeder Systems

Adequate feeding space is critical to obtaining optimum growth rates and uniformity. Most broiler house feed lines have automatic round pans that are 12 inches in diameter and designed to meet feeding requirements of 4580 birds (lower ratio for bigger birds). Feed is distributed to pans through a metal tube containing an auger. At the far end of each feed line is a control pan, which controls the run-time of the auger. When feed levels in control pans are low, a relay switch signals augers to run and distribute feed throughout the system. Benefits of a feed pan system are faster fill times, unrestricted bird movement throughout the house, less feed wastage, easy height adjustment, and no accessible moving parts while allowing broilers continuous access to feed in a comfortable manner. Feeder pan height should be adjusted daily so the base of the pan is level with the birds’ backs. The number of feed lines that are needed depends on house width. Guidelines given below are from the Arbor Acres Broiler Management Guide (2010).

Table 7. Feed Lines by House Width |

|

House Width (feet) |

Number of Feed Lines |

42 |

2 |

50 |

3 |

65 |

4 |

85 |

5 |

Each broiler chicken house typically has two 10-12 ton feed storage bins from which feed is augered into feed hoppers inside the house. Outside feed bins may be found near the middle or at one end of the chicken house. Capacity of feed storage bins should be equal to 5 days of feed consumption and feed bins should be watertight to reduce mold and bacterial growth. Two feed bins for each house allows for rapid change of feed if medication is necessary and also can be used to prevent mixing of old and new feed in the same bin if one bin is filled at a time.

Drinker Systems

Adaptation of closed water systems in the early nineties was one of the great improvements in the broiler industry. Closed water systems are a marked improvement over open systems, such as bell drinkers, cups, troughs, or open water founts, all of which resulted in an unsanitary

water supply. Closed water systems are less likely to be contaminated than open systems and, as there is better control of water usage by the birds, litter remains drier, which improves bird health. In addition, closed water systems do not require daily cleaning, which reduces labor. Closed water systems dispense water when the chickens peck at a metal trigger or nipple. Movement of the trigger up and down or side-to-side allows water to flow from the water line pipe to the nipple. A regulator located at the beginning of each line controls the rate of flow through the drinkers and can be adjusted depending on the age of birds and the drinker system. Critical to proper drinker management is checking for air locks, and ensuring an even depth of litter so broilers have uniform access to all drinkers. Drinkers should be just high enough that birds must slightly stretch to reach the trigger pin while their feet are flat on the floor. Birds should have their necks at a 45-degree angle when accessing water at the nipple.

Two types of closed water systems are used: low flow rate nipple drinkers and high flow rate nipple drinkers. Most broiler producers use low flow rate nipple drinkers, which operate at a flow rate of up to 2 fluid ounces per minute. Pressure is adjusted to meet water flow requirements and one nipple supplies water for approximately 10 chickens. A few broiler houses have high flow nipple drinkers with cups to catch water that may drip from the nipple. One nipple in high flow rate systems supplies water for approximately 12 broiler chickens. The actual number of birds per nipple depends on bird age, climate, flow rate, and design of the water system.

Water meters are an excellent tool for monitoring water usage and estimating feed consumption because the two are highly correlated. The water use:feed consumption ratio varies with ambient temperature as shown in the table on page 21 provided by the Cobb Broiler Management Guide.

Table 8. Water Use to Feed Consumption Ratio |

|

Temperature (ºF) |

Water to Feed Ratio |

39 |

1.7 : 1 |

68 |

2.0 : 1 |

79 |

2.5 : 1 |

99 |

5.0 : 1 |

Sudden changes in water consumption are a tell-tale sign of potential problems, such as stress, a feed issue, disease, or a water system leak. During hot weather, water lines should be flushed to ensure that water is as cool as possible. In the event that the main system fails, water storage tanks on the farm should have sufficient capacity to provide at least 24 hours of water at maximum consumption.

Lighting Systems

Lighting is a vital component of broiler production and represents 25-40% of electrical costs. Light intensity and photoperiod (day length) directly influence the time broiler chickens spend eating along with the general health and well-being of the birds. A period of darkness improves feed efficiency due to reduced metabolism during darkness and complements normal diurnal rhythms of bone mineralization and digestion. In addition, a period of darkness reduces the incidence of sudden death syndrome, ascites, and skeletal disorders. Most companies recommend 4 to 6 hours of darkness each day. Longer periods of darkness may exacerbate the negative effects of increased stocking density and limited feeder space.

Two types of bulbs are used for artificial lighting in solid side wall or dark curtained houses. The most common lights are 60 watt incandescent bulbs or 15-26 watt dimmable compact fluorescent light bulbs (CFL). Incandescent is the traditional light bulb used in broiler houses because of its affordability, ease of installation, and good spectral range. However, incandescent bulbs are losing popularity due to their short life span (5-6 months), high heat production, and relatively poor energy efficiency. CFL bulbs have a 60% energy savings over incandescent bulbs and produce 3 to 5 times the amount of light per watt but lack durability and lose intensity over time. Currently, light emitting diode (LED) bulbs are gaining popularity due to durability and energy savings.

Heating Systems

Heating a house is critical to brooding success. Broiler houses can be heated through convection heat and/or radiant (infrared) heat. Forced air heaters (space heaters) are convection heaters, which heat air and create a uniform temperature throughout the entire house. Chicks do not have the option of seeking a more comfortable temperature by moving to a different location. Space heaters are usually placed in the middle of a house where air movement is slow. Broiler chickens and the litter will not be warm until most air in a house has been heated.

More commonly, small, round area heaters (“pancake brooders”, canopy, infrared or radiant heaters) are placed approximately 3-5 feet above the litter and create a large heated circular area underneath the heater. Radiant heat is transferred via infrared heat waves and these heaters (spot heaters) are very efficient because they heat objects toward which the heat waves are directed – not the air. Heat waves emitted from the glowing source of radiant brooders heat birds and the litter. These heaters create different temperature zones and chicks can move to the zone that best suits their temperature needs. A combination of radiant and space heaters can be used. Radiant heaters are often the primary heat source until chicks reach 14 days of age (end of brooding period) with forced air heaters used thereafter to provide supplemental heat.

Radiant tube heaters are a third option and consist of long tubes located along the apex of the roof or along the walls. Radiant tube heaters warm the entire floor surface of the house and create a uniform environment. However, they must be carefully managed to avoid making the floor too hot and driving chicks away from feed and water.

Environmental Control Systems

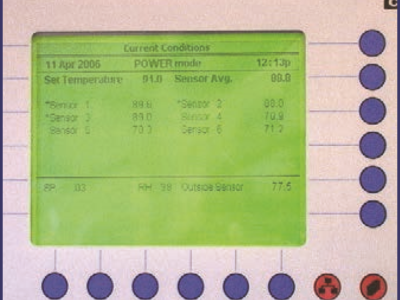

Computerized environmental controllers are available for broiler houses with natural ventilation and for broiler houses with tunnel ventilation. Environmental controllers provide real-time information on temperature, relative humidity, ammonia, carbon dioxide, and static pressure in a house and have a non-erasable memory that provides a record of environmental conditions in the house over time. Stored information includes a record of maximum and minimum house temperatures, including where and when they occurred in the chicken house. Similar data are recorded for heater and fan runtimes, relative humidity, and water consumption. Sophisticated computer control systems receive input from various thermal sensors located throughout

the house at bird height and can turn fans or heaters on or off in order to maintain house temperatures within 3°F of the desired temperature, which decreases as broiler chickens age. Most controllers have a high and low temperature alarm system and a power failure alarm system. Environmental controllers from all houses on a broiler farm can be linked to software on personal computers so data can be accessed by flock managers in their home at any time of the day or night. Flock managers can use the software to change parameters in the controllers.

Ventilation Systems

Ventilation is the primary means for controlling the environment in a chicken house. There are two types of ventilation systems: natural ventilation used in open-sided housing and power ventilation used in controlled environment housing, commonly referred to as “tunnel ventilation”. Natural ventilation requires continuous monitoring and adjustment of curtains in response to changes in temperature, humidity, wind velocity, and wind direction. Typical open-sided houses have curtains on the sidewalls that can be opened or closed. When house temperatures are warm, curtains are closed to allow a larger volume of air to move through the house. On hot days, circulation fans can be used to increase the rate of air exchange and foggers or misters can be used in combination with the fans to create an even greater cooling effect. When house temperatures are cool, curtains are closed to restrict the flow of air. The air exchange rate in natural ventilation houses depends on outside winds with mechanical assistance from fans.

Power ventilation systems provide more control over air exchange rates and air flow patterns, which allows flock managers to create more uniform conditions within a house. Electric exhaust fans pull air out of a house, which creates a negative static pressure inside the house and brings outside air into the house through computer-controlled openings in the sidewalls. The speed of air entering a house is determined by the amount of negative pressure (vacuum) in the house, which is controlled by matching the inlet area and fan capacity. “Migration fences”, usually composed of lengths of 10” drainage pipe, are placed across the house to form three or more areas in the house. These keep the chickens distributed uniformly in the house and prevent them from migrating toward the air inlet end of the house where there is more light and piling up.

The objectives of ventilation are to provide adequate oxygen to support the metabolic needs of the chickens, control relative humidity to maintain litter conditions, and remove carbon dioxide (CO2), carbon monoxide (CO), dust, and ammonia. Carbon monoxide may be produced if dust partially blocks air inlets on brooder stoves resulting in inefficient combustion of natural gas or liquid propane fuel. Because moisture is constantly introduced into a chicken house through bird excreta, bird respiration, spillage from drinkers, and fuel burned in brooder stoves; proper airflow is vital to prevent excess moisture accumulation in the litter. Ammonia is produced in the presence of moisture by bacterial breakdown of uric acid in bird excreta that accumulates in the litter. Prolonged exposure to high levels of ammonia causes structural damage to the respiratory system (>25 ppm), damage to the eyes (>60 ppm), and has a detrimental effect on body weight and feed efficiency. Limiting the amount of litter moisture through proper ventilation significantly reduces ammonia formation. The quantity of moisture and ammonia removed through ventilation is influenced by the temperature and humidity of incoming air, but is more dependent on its speed and direction. If inlets direct incoming air towards the chicken house ceiling, air temperature and moisture-holding capacity of incoming air will increase. Every 20°F rise in the temperature of incoming air cuts its relative humidity in half, improving its ability to remove house moisture.

Ventilation rates should be slowly increased each week as birds age to keep ammonia and moisture in check. When more than the minimum air exchange rate is needed, temperature sensors override the minimum ventilation timer to keep fans running. Ventilation should keep relative humidity at 70% or below to ensure that moisture will evaporate from litter. Relative humidity should remain above 50% to ensure that adequate moisture is left in litter to prevent dusty conditions.

Litter

Choosing the type of bedding material used in a broiler house is an important decision. Bedding dilutes excreta, absorbs fecal moisture, promotes drying of manure, provides a cushion for breast muscle and feet, and insulates the floor during cold weather. A good bedding material should be lightweight, highly absorbent, able to dry quickly, soft and compressible, inexpensive, useful as fertilizer, non-dusty, and free of pesticide residues, mold, and pathogens. The most common types of bedding are rice hulls and pine shavings, either separate or as a mix. While these are the preferred choices, rice hulls are now being burned for energy and pine shavings are used to manufacture particleboard, making these sources expensive. Alternative beddings sources with less desirable qualities include peanut hulls, chopped wheat or pine straw, pine bark, hardwood shavings, sawdust, chopped straw, shredded paper, peat moss, and sand. New bedding should be placed in a house at a depth of 3-4 inches.

Reference: "USDA APHIS | FAD Prep Industry Manuals". Aphis.Usda.Gov. 2013. https://www.aphis.usda.gov/aph...

The manual was produced by the Center for Food Security and Public Health, Iowa State University of Science and Technology, College of Veterinary Medicine, in collaboration with the USDA Animal and Plant Health Inspection Service through a cooperative agreement.