Essential ventilation management, part 3: measuring, monitoring and maintenance

This series has been written with the guidelines for a house in a climate that may experience four seasons. As such the series will cover the three modes of ventilation (minimum, transitional, tunnel). In most countries and climates around the world, these three modes of ventilation are necessary in order to have the best chance of maintaining bird comfort.Part of Series:

< Previous Article in Series

Further measuring and monitoring

- House tightness (see Ventilation How To 02; How To…Measure Air House Tightness)

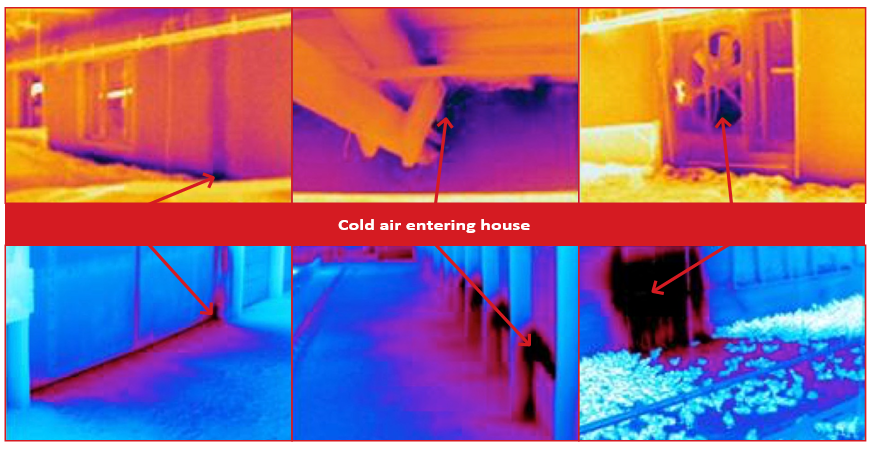

- Measure before flock placement or when suspected issues occur (e.g. if house pressure decreases, litter quality deteriorates, or bird behavior changes)

- Use a smoke test (outside the house) to show air entry or turn lights off and stand in dark to see where cracks are.

- Measuring fan capacity (see Ventilation How To 03; How To…Measure Fan Capacity)

- Measure revolutions per minute (RPM) using a digital tachometer and compare to manufacturers specifications

- Refer to manufacturers performance data (pressure vs fan capacity)

- Air speed (cross ventilation)

- Use smoke test or cassette tape method to determine if air speed is sufficient to reach the peak of the roof. tunnel ventilated house)

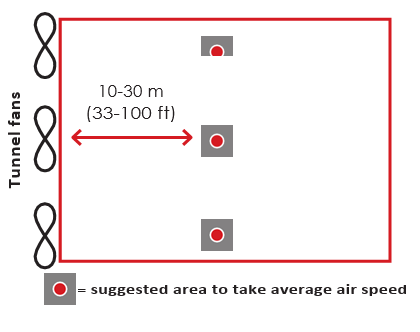

- Tunnel ventilation (see Ventilation How To 05; How To…measure average air speed in a

- Measure in 3-4 places across width of house at bird level

- Measure approximately 10-30m (33-100 ft) away from tunnel fans

- Use Average

Key maintenance management

- Check system operation;

- check alarm systems; there should always be an alarm system that is independent of the control system.

- check auxiliary electricity generator.

- check curtain operation if using open-sided housing.

- check electrical panel and its elements.

- calibrate inside and outside sensors every flock.

- make sure outside temperature sensors are never in direct sun.

- check fogger and pad cooling systems.

- check fans are in good working order.

- check inlets are calibrated to open uniformly.

- check air pressure sensor tubes are not blocked and the tube to the outside is not affected by wind.

- calibrate the pressure sensor reading.

- Check water quality; a reduction in the physical/chemical quality of water (for example due to contamination or periods of hot weather) will have a negative impact on filter condition where water cooling systems are fitted.

- Clean all water filters and replace if necessary.

- Check that temperature and humidity sensors for foggers are protected from water. Water (and/or dust) on the surface of the sensor will reduce sensor accuracy and may affect operation of the ventilation and cooling systems.

- Clean evaporative cooling pads and/or foggers. Remove inlays and clean sediment, replace worn elements.

- Have spare parts available (such as fan belts, pump spares filters etc.) in case of breakdowns.

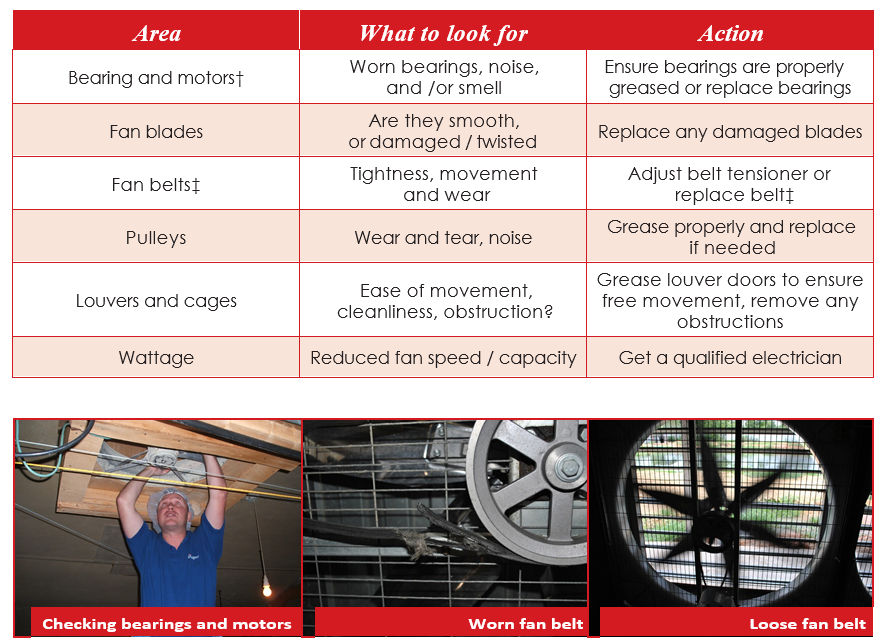

- Complete fan maintenance checks:

- Cooling pad / pump maintenance.

- Make sure the sump is covered.

- Empty sump a minimum of once every 2 weeks (more often may be needed depending on water quality).

- Completely dry the cooling pad out once a day.

- Keep pads shaded if possible (make sure that air flow to the pad is not restricted).

- Use recommended products to control algae.

- Clean filters weekly and test air flow regularly.

- Ensure water pipe drip holes are not blocked.

- Follow the pad manufacturers maintenance recommendations.

Key management tasks

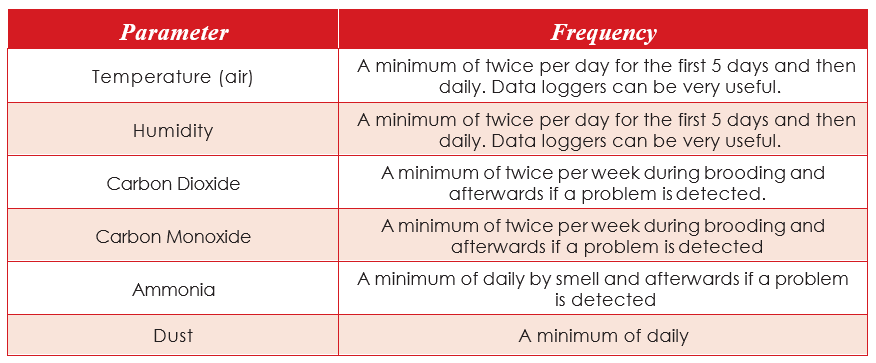

- Routinely record environmental and air quality parameters.

- Check position of sensors. They should be:

- at bird height

- evenly spread along length of house

- out of direct line of heating system

- located out of direct sunlight - outside temperature sensors located out of direct sunlight.

- Manually verify the accuracy of electronic sensors controlling automatic systems once per week.

- Regularly remove dust and feathers from, screens and fan blades, light traps, and louvers. A build-up of dirt will significantly reduce ventilation efficiency.

Open or curtain-sided housing

For more information on ventilation in open or curtain-sided houses please refer to the document: A Guide to the Management of Open-Sided Houses.

Broilers vs breeders

- For breeders reducing house temperature during feeding until 2 hours after feeding can help to dissipate excess heat and reduce dust – exact temperature reduction should be determined by monitoring bird behavior.

- Be aware that air flow may be different in a breeder house than in a broiler house due to additional equipment such as slats and nests.

Useful calculations

Minimum ventilation

Ventilation Rate

- Minimum ventilation [m³/hr] = number of birds x ventilation rate per bird [m³/hr/bird]

- Minimum ventilation [cfm] = number of birds x ventilation rate per bird [cfm/bird]

Cycle Timer

- ON time = (min vent [m³/hr] x cycle time [sec]) ÷ (total min vent fan capacity [m³/hr])

- ON time = (min vent [cfm] x cycle time [sec]) ÷ (total min vent fan capacity [cfm])