If you reduce the content of soybean meal in your starter feed, be careful what you replace it with!

We have recently highlighted the need to reduce the content of soybean meal (SBM) in broiler starter diets below 30% in order not to exceed the upper limits of antinutritional factors (ANFs) that can compromise the intestinal health and the productive performance of chickens (Blanch 2020 a, b; Blanch 2021).On the other hand, the amino acid profile of SBM is, without a doubt, very suitable to meet the needs of young chicks. Therefore, if we reduce SBM below 30% in starter diets, we need to fill the gap left by the mentioned reduction in the feed formula with other sources of protein. Although there are protein sources, other than soy, that can be used in starter feeds, they also present certain risk factors that can compromise the health and welfare of chickens and consequently their growth and performance (Blanch, 2021 b). Subsequently, the inclusion of these alternative proteins to SBM in starter feed is constrained too.

Ideally, the amount of SBM that is removed from the starter feed formula should be replaced by another product with the same amino acid profile, suitable for chickens, but without ANFs. In this sense, there are various processed soy products on the market to minimize soy ANFs content in starter feed. The content of ANFs in these products is not the same for all of them due to the characteristics of each treatment:

- Extrusion: some ANFs (e.g., trypsin inhibitors, beta-conglycinin) are reduced by heat during the extrusion process. However, there is a risk of damaging the protein quality due to the high temperatures reached. On the other hand, the indigestible oligosaccharides stachyose and raffinose are not affected by the extrusion process. This is a major disadvantage in poultry because these oligosaccharides trigger diarrhea, wet litter and consequently footpad dermatitis (FPD). Extrusion is also the most used treatment to produce full fat soy. However, above a certain temperature, oil oxidation will become an additional problem.

- Water-alcohol extraction: after oil extraction, the solid fraction -or soy flakes- goes through a further extraction process using water and alcohol solution, to solubilize oligosaccharides and, at the same time, avoid protein extraction. The only minor issue of this treatment is that oligosaccharides are not completely removed during the extraction process, which constitutes a risk of FPD. Also, the heat treatment involved in this process to eliminate TIA may affect the structure of the protein and, therefore, its digestibility.

- Fermentation: fermented soybean meal is produced to reduce ANFs too. However, the batch-to-batch variation is very wide. Thus, in each fermented product, at least one of the ANFs is hard to control. The reason for the broad variation is that sugars in soy break down differently depending on the strain of the bacteria used, affecting the final protein content. In addition, if the temperature is too high, the protein will denature and the amino acids will establish Maillard reactions with the sugars, compromising the nutritive value of the end product.

- Enzyme treatment: the use of specific enzymes to reduce ANFs means that the final product has an extremely low oligosaccharide content and therefore, the risk of FPD is substantially reduced. Also, a consistently low content of the antigen beta-conglycinin and trypsin inhibitor activity is achieved with this enzymatic treatment. Furthermore, this is a gentle process that does not reach high temperatures and, consequently, the risk of affecting the protein structure is much lower than with other treatments.

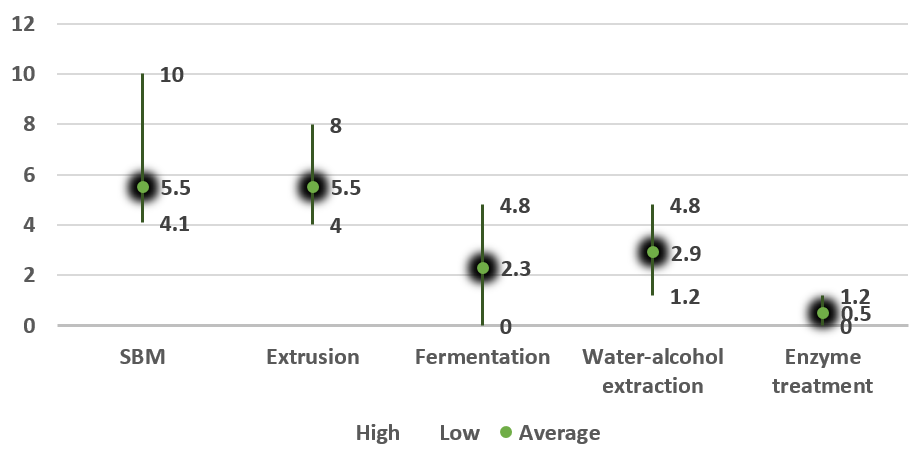

In Figure 1, the content of indigestible oligosaccharides stachyose and raffinose in several processed soy products are shown (internal data from Hamlet Protein).

In short, reducing the level of SBM meal in chicken starter diets is becoming a common practice in modern poultry production. We must be very aware of the type of protein source that we use to fill the void left by that SBM reduction in the feed formula. Our objective should be to minimize the amount of ANFs without giving up having a good supply of protein and amino acids.

| References | ||||

|---|---|---|---|---|

| Blanch A. (2020a). Soy trypsin inhibitors do affect the growth and gut health of chickens. https://www.thepoultrysite.com/articles/soy-trypsin-inhibitors-do-affect-the-growth-and-gut-health-of-chickens | ||||

| Blanch A. (2020b). Soy oligosaccharides and beta-conglycinin, behind gut inflammations, wet droppings and footpad dermatitis in chickens. https://www.thepoultrysite.com/articles/soy-oligosaccharides-and-beta-conglycinin-behind-gut-inflammations-wet-droppings-and-footpad-dermatitis--n-chickens | ||||

| Blanch A. (2021). Bird welfare in poultry production: dietary soy α-galactosides do play a role! https://www.thepoultrysite.com/articles/bird-welfare-in-poultry-production-dietary-soy-α-galactosides-do-play-a-role | ||||