US Poultry Industry Manual - In-line eggs

Learn more about off-line farms and in-line shell egg operationsPart of Series:

< Previous Article in Series Next Article in Series >

Editor's Note: The following content is an excerpt from Poultry Industry Manual: The Foreign Animal Disease Preparedness and Response Plan (FAD PReP)/National Animal Health Emergency Management System (NAHEMS) Guidelines which is designed to provide a framework for dealing with an animal health emergency in the United States. Additional content from the manual will be provided as an article series.

In-line Eggs

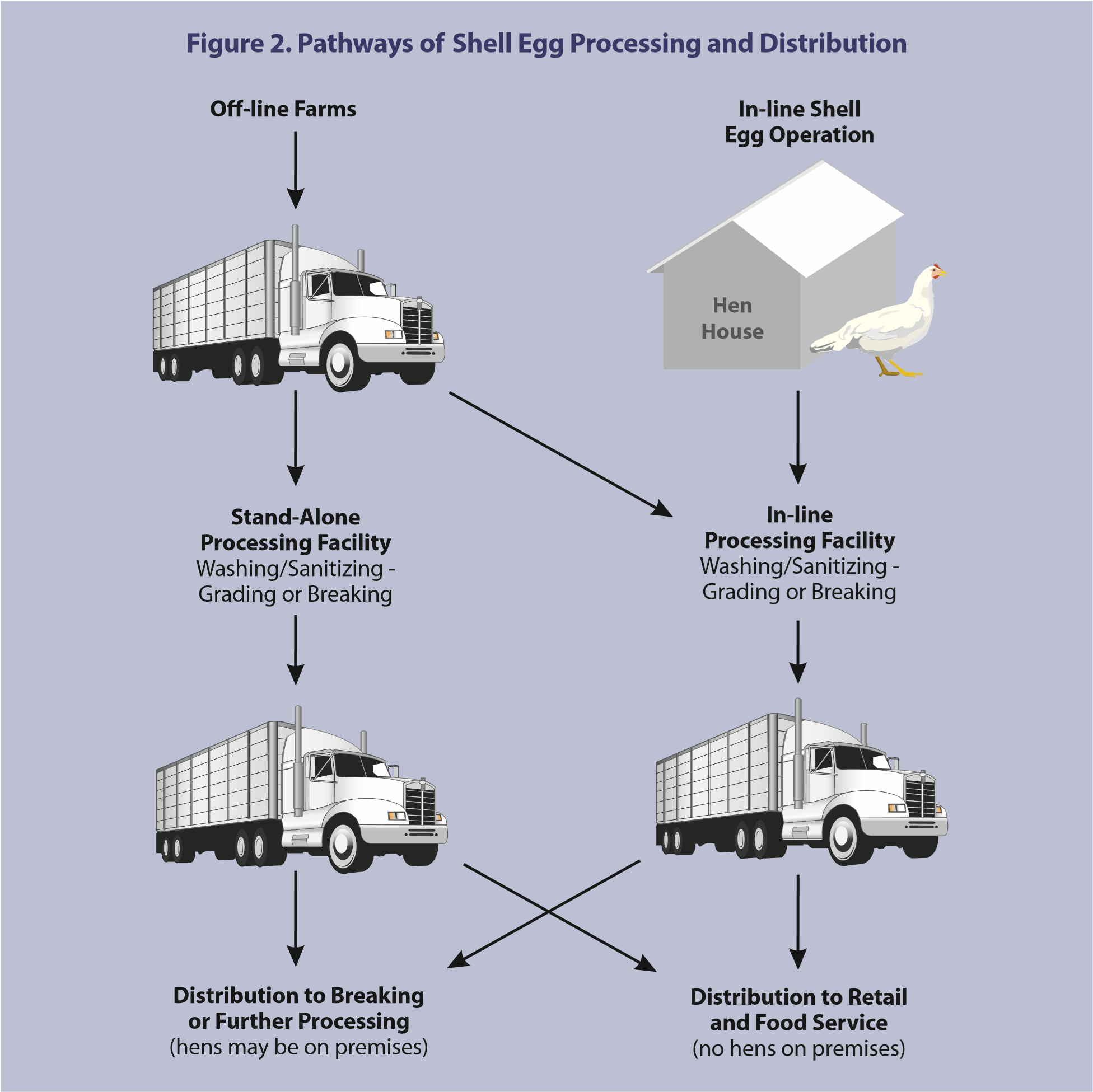

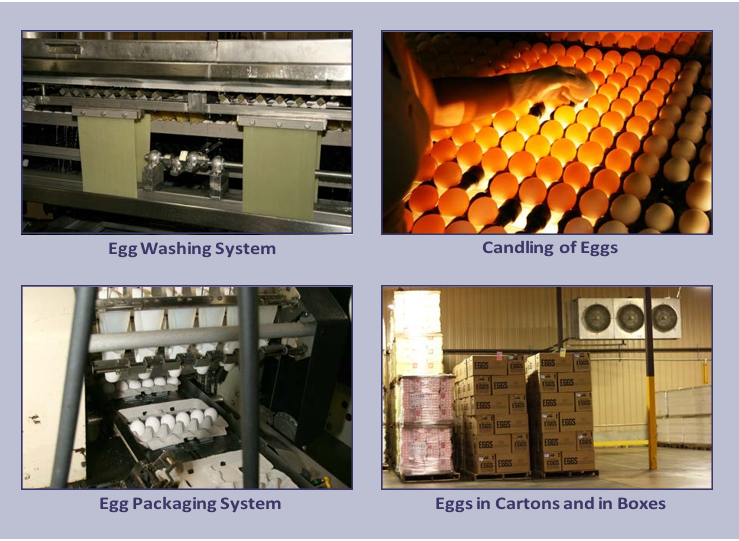

Highly computerized egg processing equipment accepts eggs entering the egg processing plant on conveyor belts and automatically washes, candles, weighs, and places eggs into cartons containing different sized eggs (small, large, extra-large, or jumbo). The capacity of egg processing equipment influences the number of laying hens on a farm. Egg producers strive to have sufficient numbers of hens to keep the processing equipment operating at full capacity during an 8-hour shift. Some in-line egg operations purchase eggs from off-line farms so that the egg processing equipment can be more fully utilized. Egg processing plants require a dry storage room to hold packing materials, a room for the processing equipment, and a cold storage room to hold eggs after they have been placed in cartons.

Off-line (nest run) eggs

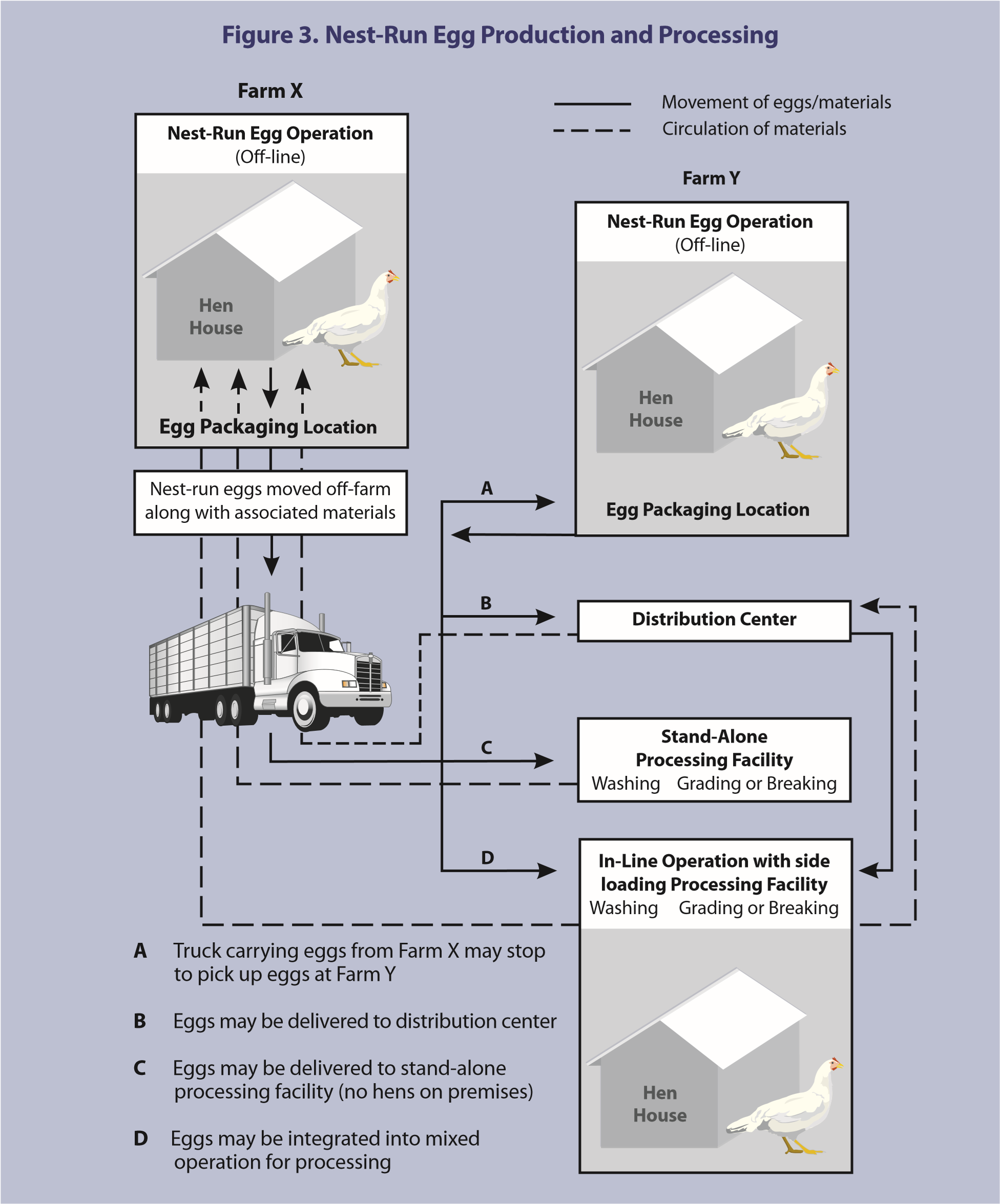

At least 20% of eggs are packed off-line. An in-line egg operation may receive eggs from one or more off-line operations and this process is called “side loading.” Nest run eggs from off-line farms may be transported to the “transfer room” of an in-line facility. In the transfer room, shell eggs from off-line operations are removed from their bulk packaging (pallets, racks, and flats) and introduced via vacuum lifts to an egg conveyor belt prior to washing. Nest run eggs are merged with eggs from the in-line facility on the egg conveyor belt. Nest-run eggs may be marketed via the “spot market” or as part of contractual agreements made between producers and processors of shell eggs or egg products.

Steps in whole shell egg processing

Approximately 70% of eggs produced in the United States are sold as whole shell eggs. Shell egg operations include 1) washing; 2) sanitizing external egg surfaces; 3) candling/inspection of shell eggs; 4) weighing, grading and packaging shell eggs; and 5) storage and transport to market. Egg washer conveyors move eggs into the egg washing machine where they are washed with detergents. Contamination of internal contents is minimized during washing by prohibiting immersion of eggs in the wash water and requiring that the temperature of the wash water be maintained at 90°F or higher, and at least 20°F warmer than the temperature of the eggs to be washed. USDA’s Agricultural Marketing Service recommends an egg washing temperature of 110°F which improves egg cleaning. Immediately following the detergent wash, shell eggs are sanitized by rinsing with potable water containing an approved sanitizer, such as chlorine or quaternary ammonium compounds. Chlorine rinse water must contain between 100 ppm and 200 ppm chlorine. Sanitizing the external surface of the egg does not remove pathogens that may be present in the albumen or yolk, such as Salmonella enteritidis. After the sanitizing rinse and drying, egg processors have the option of coating the surface of shell eggs with a food grade mineral oil to conserve albumen quality. Candling is a process wherein eggs are passed over an intense light that allows internal and external defects to be detected. Eggs with internal defects are identified by workers or by computerized detection equipment and removed for disposal as inedible egg products. Eggs with external defects, such as fecal material on external shell surfaces, are removed from the line for rewashing. Eggs are weighed individually by specialized computer-controlled machines and automatically directed into separate packing lanes based on individual egg weights. Eggs may be placed on cardboard, foam or plastic flats or in cartons containing 12, 18, or 30 eggs. Egg cases can be stored on site in a cold storage room or immediately transported to distributors or customers. Cold storage rooms must be refrigerated and capable of maintaining an ambient temperature no greater that 45°F (7.2°C). Shell egg cooler rooms must be equipped with accurate thermometers to monitor cooler room temperatures and a device to measure relative humidity. Humidifying equipment capable of maintaining sufficient relative humidity to minimize shrinkage should be used. Shell eggs destined for breaking plants may be temporarily held at a warehouse or go directly to an egg breaking facility. U.S. egg producers pack about 140 million cases of eggs each year.

Reference: "USDA APHIS | FAD Prep Industry Manuals". Aphis.Usda.Gov. 2013. https://www.aphis.usda.gov/aph...

The manual was produced by the Center for Food Security and Public Health, Iowa State University of Science and Technology, College of Veterinary Medicine, in collaboration with the USDA Animal and Plant Health Inspection Service through a cooperative agreement.