2021 IPPE: How has COVID-19 impacted the US broiler industry?

Ashley Peterson, Senior VP at the National Chicken Council, offered insights about COVID-19's impact on poultry processing plants.Part of Series:

< Previous Article in Series Next Article in Series >

The National Chicken Council’s members produce about 95% of the broiler meat in the US, and NCC advances industry policies on Capitol Hill, within the executive branch and the media.

US poultry industry

- About 29 companies are involved in raising, processing and marketing chickens.

- The NCC works with about 25,000 family farmers across the US who raised almost 9 billion broiler chickens in 2019, weighing more than 56 billion pounds live weight which resulted in 47 billion pounds of ready-to-cook chicken.

- The US is the second largest exporter of chicken behind Brazil.

- The US exported about 17% of its production in 2019.

- Americans consume more chicken per person than anyone else in the world, eating about 98 pounds of chicken per capita.

- Chicken is the #1 protein consumed in the US.

Industry evolution:

- Back in 2002, the top 20 chicken companies produced 91% of the total US production of chicken meat, processing about 153 million birds per week.

- In 2019, the top 20 chicken companies produced 98% of the total chicken meat, processing 165 million birds per week. The top 10 chicken companies produced about 82% of our total US production of chicken meat, processing 134 million birds per week.

- Over the past few years, there's been a drastic increase in birds that are raised without antibiotics.

- The US industry has seen about a four-fold increase over the last eight years in organic production, and conventional production is about 45% of current production (2019 data).

Impact of COVID on the broiler chicken industry

In the middle of March, Americans, like consumers in other parts of the world, found empty grocery store shelves, including in the meat case, as consumers hoarded food, toilet paper and other essential items.

© Ashley Peterson, NCC

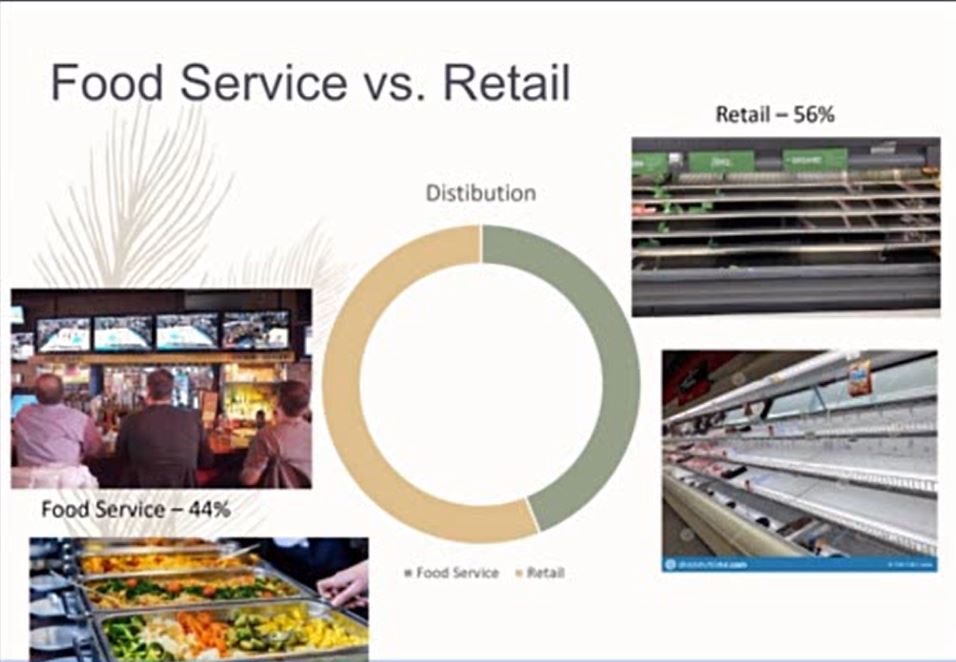

About 44% of chicken production goes into food service. Thus, one of many industry challenges was taking products that would normally go to food service and diverting some of that meat to retail.

“When we send items to food service, a lot of times they're going in 20-pound bags or 40-pound boxes," she said. "One of the initial challenges the industry had was diverting products, getting appropriate packaging material and getting the appropriate labels to get things to retail in a timely fashion to fill those shelves and feed Americans.”

© Ashley Peterson, NCC

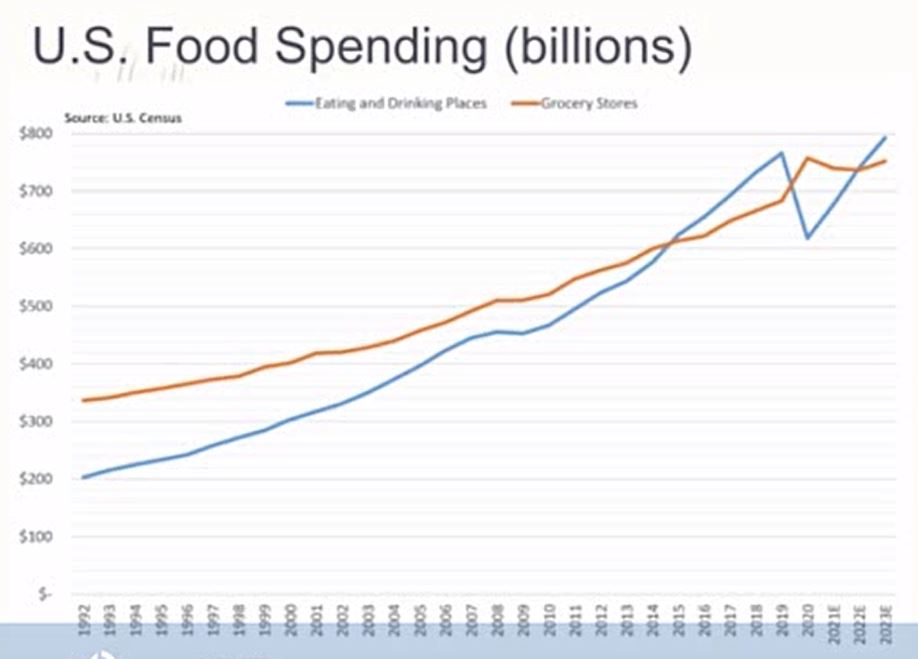

Looking at changes over time in food spending, the blue bar (chart above) shows a drop down in food service. The orange bar shows grocery store spending.

“We did see a significant increase in grocery store sales and a drastic decrease in people going out to eat, which wasn't unexpected,” she explained. “Restaurants closed and you're going to need to start cooking at home, and people are very familiar with cooking chicken, so that was a common commodity that people were looking for.”

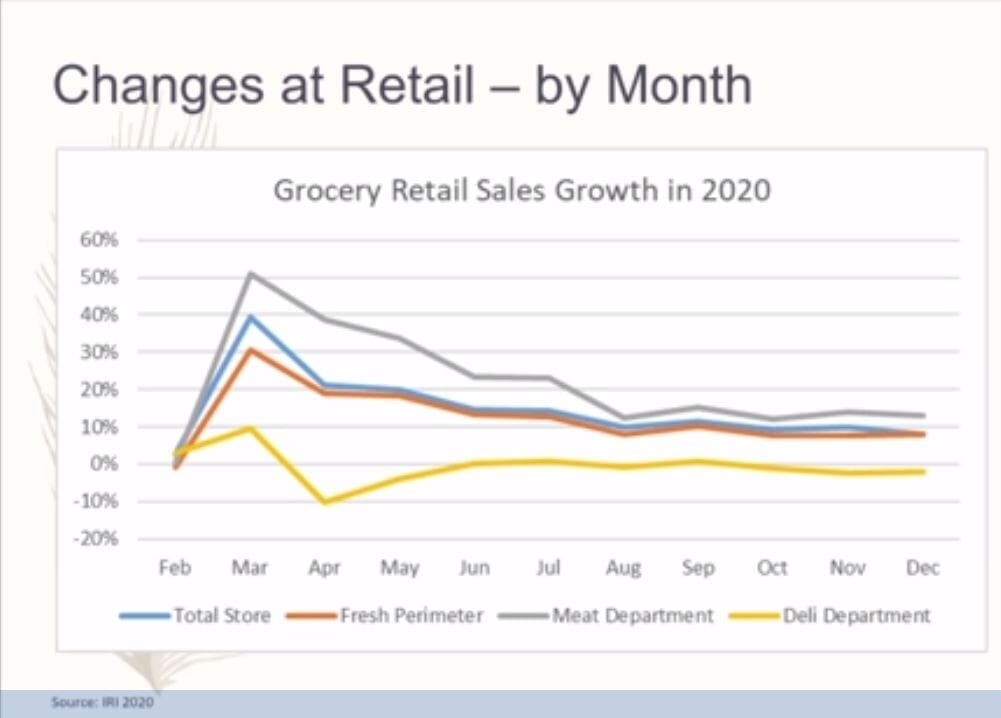

Chicken and hamburger were the two most sought after proteins. In March and April, there was a drastic increase in grocery store/retail sales. This included an increase in meat department sales and fresh foods, including fruits and vegetables. Over the last few months, there has been a 9.1% volume increase on chicken purchasing, according to Peterson.

Throughout the pandemic, restaurants have worked to diversify, not only their menu, but their carry out options. Some foods don't carry out very well, so those restaurants have struggled a little bit more than others. Restaurants has also learned how to package certain food stuffs in way to ensure that when it gets home, it's almost as it would have been if you could have eaten at the restaurant.

© Ashley Peterson, NCC

Who’s in charge anyway?

Early on, the US industry had challenges with who was in charge, with direction coming from many different groups.

“We would have state health departments who had a different perspective on what our industry needed to be doing with regard to maintaining the safety and health of our employees than did local health departments. The CDC then came out with their set of recommendations in April,” she noted.

“You have the governor calling on CEOs of chicken companies. You have OSHA with certain standards and coming in and wanting to do inspections at plants. We had USDA and we have the Food Safety and Inspection Service - we have those inspectors in our plants all the time. USDA was working hard to help make sure we had the appropriate staffing available so that we could keep operating. Trying to weave between all of these different groups who had different asks and asks that changed over time as we learned more about the spread of COVID was certainly a challenge.”

In late April, the Trump Administration issued an executive order that essentially gave the former US Secretary of Agriculture, Sonny Purdue, the powers of the president in order to make sure that meat and poultry processors could continue to operate, provided they were meeting CDC and OSHA guidelines.

While never executed per se, the order was designed to help companies fulfill their contracts and continue providing meat and poultry to consumers, according to Peterson. USDA worked very hard to ensure the industry could keep operating while also maintaining the safety of their workforce.

Of critical importance, Peterson said was ensuring the industry is doing everything they can to protect employees.

“One of the things that sets the meat and poultry industry apart is that we already do a lot of things and had done a lot of things to ensure the safety of our employees,” she said. “Granted, we needed a lot more PPE than we had in the past, but donning PPE with something that you do that when you go into a processing plant.”

In April, the CDC and OSHA came out with some interim guidance for the meat and poultry industry focusing on two areas.

- Engineering controls

- Physical barriers - it was learned early on that not all physical barriers are the same.

- Handwashing stations – increasing access to hand washing stations, sanitizing stations, and communicating that they were available for use for employees.

- Administrative controls

- Staggering workers’ breaks for social distance purposes in break rooms.

- Visual cues showing proper spacing.

- Carpooling – doing this safely without spreading the virus.

- Education and training – what does social distancing mean, what are the virus symptoms, etc.

“Our industry has a unique challenge because if you look at the number of employees per thousand square foot of space, meat processing is at the very top; we have a lot of people within our establishment doing work,” she said. “We are quite automated, especially in first processing, but in second processing, there are a lot of people, depending on what product you're making, who are cutting up chickens.

"Some of the things that we implemented as an industry and some of the things that we had done well before CDC and OSHA came out with their guidance, was putting barriers in place so that people could come to work on the processing lines and not have to worry about getting sick from somebody next to you or spreading any potential viruses around. The PPE is something that we had already done, but it's been PPE on steroids, I would say.”

Taking employee temperatures and extra sanitation focusing on common touchpoints and common areas was also set up. There were challenges procuring PPE that occurred and times when FEMA took product that was allocated to member organizations.

“We have a very diverse population within our establishment speaking well over a dozen different languages within one establishment itself, so making sure that we could adequately communicate to everyone has been really, really important,” she noted.

Overcoming challenges

Social distancing - maintaining six feet apart because plants have not been set up to accommodate this. However, barriers have been installed to the right and left the employee, and in some cases in front of the employee when people are facing each other, for example in a de-bone line.

Temperature monitoring – early on, there were some inaccuracy issues, but it’s gotten better. When people come in from outside, they're already cold, so it can be difficult to get an accurate reading. Getting an internal temperature is different than an external temperature like a forehead scan. However, temperature monitoring has made employees more comfortable to come to work.

Testing – some member companies have made testing mandatory, while others have voluntary testing. There are also differences within people's religion and/or beliefs that may influence whether they want to get tested, so employers are conscious of those differences.

Education - being able to communicate to everyone is very important. CDC has offered resources to assist with this.

Vaccination

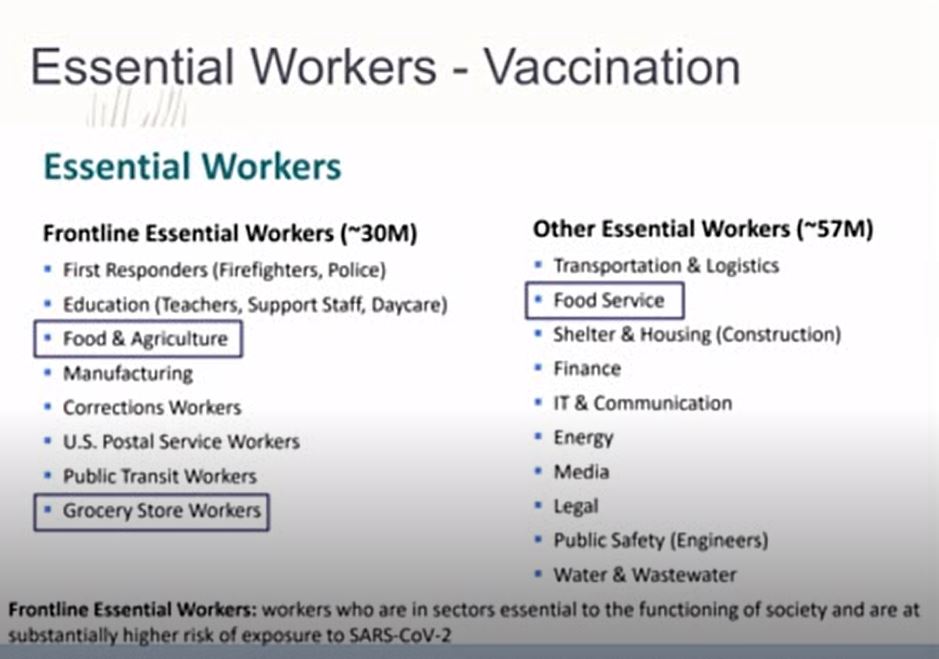

With two vaccines approved in the US, there have been 22.7 million doses administered so far.

“When we talked to the CDC earlier in December, they had said that meat and poultry workers should be getting their vaccines in late January. We're in late January, and as far as I'm aware, none of our members have gotten the call that says, ‘okay, it's time,’” she said. “One thing we are talking with our members about is preparing for the vaccine.”

Food and agriculture workers are essential frontline workers, which is part of the total group of about 30 million essential frontline workers. Peterson is hopeful that members will get access to a vaccine for employees within the next several weeks.

© Ashley Peterson, NCC

Is this the new norm?

Peterson said 10 months in, the changes that have been made in processing, may become the new norm. CDC and OSHA are expected to update their guidance to the industry. So, time will tell.

Peterson does expect that COVID will change the future of automation, virtual audits and enhanced imaging systems in the industry.

“There are is a lot of opportunity to make current technologies better and to help us do some things, so we don't necessarily have to have somebody standing there doing a particular job,” she said.