Is Mold Growth Hurting Your Performance?

By Frank T. Jones, Cooperative Extension Section Leader, Center of Excellence for Poultry Science at the University of Arkansas's Avian Advice - Unexplainable poor performance can occur from time to time. While production problems can originate from innumerable sources, some common situations should not be overlooked. When management factors are good and birds still perform poorly, it may be time to take a closer look at the feed bins and pans to determine if mold growth is the source of the problem.| The Author | |

Dr. Frank Jones Extension Section Leader |

|

What Can Happen

Over 20 years ago a survey was conducted with five North Carolina broiler companies. Six

broiler farms were selected from each company for a total of thirty farms. Farms that

participated in the study were chosen based on the productivity indicated by the previous year’s

records. Two farms from each company were classified as above average in productivity, two

were average in productivity and two classified as poor. Schedules were arranged so that chicks

arrived at each farm within a few days of each other and were caught at the end of the flock

within a few days of each other. One flock was surveyed and feed samples were collected

weekly from the feeder pans on each farm. Table 1 contains data collected from this study.

| Table 1. Molds, Aflatoxin and Broiler Production | ||||||

| Productivity Classification | No. of Farms | Age (Days) | Wt (lbs) | Feed Conv | Mold (Count/g) | Aflatoxin (ppb) |

| Above Average | 10 | 52.6 | 3.88 | 2.13 | 8,000 | 6.13 |

| Average | 10 | 51.9 | 3.83 | 2.15 | 35,000 | 6.49 |

| Below Average | 10 | 52.8 | 3.79 | 2.16 | 43,000 | 13.99 |

| From Jones et al. 1982. | ||||||

It should be obvious from the weights and feed conversions in Table 1 that these data are over 20 years old! However,

please note that as farm productivity gets progressively poorer, weights are lighter and feed conversion worsens. While we all

realize that there are many factors that affect performance, these data suggest that molds and aflatoxin are related to performance.

Since farms in the study were on the same placement and catch schedule, they likely got feed at about the same time.

Consequently, it seems logical to assume that when feeds arrived on each farm, they contained about the same number of molds.

Yet, mold counts from farms with below average productivity are seven times higher than those from farms that were above

average in productivity.

What Happens When Molds Grow in Feeds

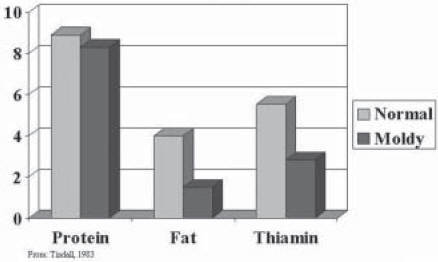

Molds can grow on almost anything. As they grow, nutrients are destroyed and toxin are released. When molds grow in

feeds they use up nutrients and vitamins that the birds should be getting. The data in Figure 1 illustrate how mold growth can

destroy protein, fats and thiamin in grain. Molds can produce toxic substances call mycotoxins (such as aflatoxin). There are

over 250 known mycotoxins produced by many different mold strains. When birds are exposed to high levels of mycotoxins they

can cause gut irritation or digestive system problems, skeletal or leg problems, nervous system symptoms and impaired immunity.

However, in most field cases birds are exposed to low levels of mycotoxins, which produce non-descript symptoms. Birds may

just not seem right, but show no major signs.

Figure 1: Mold Destruction of Protein, Fats and Thiamin in Grain  |

How can mold growth happen in feeds?

Molds can be found virtually anywhere in the natural environment. It is common for pelleted feeds to contain hundreds of

mold spores per gram. Molds will grow whenever conditions are right for their growth. The lack of moisture is most often what

prevents molds from growing in feeds. While the overall conditions in the feed handling system and poultry house may not

promote mold growth, molds will tend to grow in very small areas where conditions are right for growth.

A general depiction of mold metabolism can be seen in Figure 2. It is not necessary to thoroughly understand mold

metabolism. However, it is important to realize that as molds grow they produce their own moisture. This metabolic moisture

means that the process of mold growth can feed on itself and get faster as it gets going. This moisture also means that the higher

the mold count the greater the potential for mold growth.

How to Control Mold Growth

There are three primary factors that control mold growth. These factors are related to each other and each must be

addressed. Control of mold growth in feeds can be accomplished by keeping moisture low, maintaining feed fresh, and keeping

equipment clean.

Moisture Control

Moisture is the single most important factor in determining if and how rapidly molds will grow in feeds. Moisture in feeds comes from the environment in which the feed is stored or handled. To control mold growth, begin by controlling the obvious sources of moisture in the feed handling and storage equipment. These sources may include leaks in feed storage tanks, augers, and roofs. However, it is important to realize that feed moisture changes in relation to the environment. Since birds add moisture to their environment by respiration and defecation, the air in houses can be very humid. Feed that was initially very low in moisture content will gain moisture when placed in a humid environment. This means that it is crucial to provide adequate ventilation for control of humidity in the house.

Keeping Feed Fresh

Time is required for both mold growth and mycotoxin production to occur. It is therefore important to have feeds delivered

often so that it will be fresh as possible when consumed. Feeds should generally be consumed within 10 days of delivery. It is

equally important to manage the feed delivery system to ensure that feeds are uniform in freshness. Field surveys have shown that

poultry farms producing birds with the poorest performance were those with the most feed in their feeder pans. On these farms,

the feeds contained the greatest amount of moisture and had the highest number of molds. If the feeder system is allowed to keep

the feed pans full at all times, the feed in the pans will be significantly older than that in the storage tank.

Birds will tend to eat

primarily the feed in the top layer. The feed at the bottom of the pans will age, providing greater opportunities for molds to grow

and may hurt performance. To prevent this problem, the feeder system should be turned off weekly. The birds will then be forced

to clean up all of the feed in the feeders before it becomes excessively old. A similar principle applies to feed storage tanks. The

feed next to the wall is last to exit the tank and therefore stays in the tank the longest. The feed in contact with the wall is also the

only portion of the feed that changes appreciably in temperature. These factors make feed in contact with the wall susceptible to

moisture migration and mold growth. It is best to completely empty and clean one tank when the new delivery is in the other tank.

Equipment Cleanliness

If feed is delivered to farms where old feed is lodged or caked in the feed storage or delivery systems, this old feed is often very moldy and may “seed” the fresher feed it contacts, increasing the chances of mold growth and mycotoxin formation. To address this problem, caked, moldy feed should be scraped or brushed off and leaky spots should be sealed. When bins are extremely caked with feed, it may be necessary to sand blast the bin. Feeder pans should be disassembled and areas that contain caked moldy feed should be brushed to bare metal or plastic. It is important to remember to avoid the use of water in cleaning since moisture encourages mold growth.

Summary

Molds are present everywhere in nature and grow readily in feeds if conditions are right. When molds grow on feeds they destroy nutrients that are meant for our birds and they may produce mycotoxins that also hurt performance. To control mold growth in feeds, protect feeds from moisture, ensure that feeds are fresh and keep equipment clean.

References

Jones, F. T., W. M. Hagler and P. B. Hamilton. 1982. Association of low levels of aflatoxin in feed with productivity losses in

commercial broiler operations. Poultry Science 61:861-868.

Tindall, W. 1983. Molds and feeding livestock. Animal Nutrition and Health, July-August, p 5.

Source: Avian Advice - Winter 2005 - Volume 7, Number 1