US Poultry Industry Manual - production cycle of turkeys

Learn about breeding turkeysPart of Series:

< Previous Article in Series Next Article in Series >

Editor's Note: The following content is an excerpt from Poultry Industry Manual: The Foreign Animal Disease Preparedness and Response Plan (FAD PReP)/National Animal Health Emergency Management System (NAHEMS) Guidelines which is designed to provide a framework for dealing with an animal health emergency in the United States. Additional content from the manual will be provided as an article series.

Production Cycle of Turkeys

Fertile eggs are produced on breeder farms by hens that are periodically inseminated artificially with fresh semen from tom turkeys maintained separately from the hens. Eggs are usually cleaned, surface disinfected, and stored in an egg cooler on the breeder farm for 1-4 days before being transported to a hatchery where they are held for another 3-7 days before being placed into the incubator (setter). After approximately 25 days of incubation, eggs are transferred to the hatcher where they remain until the poults hatch at around 28 days. Poults are sexed and serviced (see 2.3.1) at the hatchery, taken to either hen or tom farms where they are grown to market weight, loaded onto transport trucks, and taken to the plant where they are processed (see 4.4). Product from the processing plant is shipped to distributors for additional processing or sale.

Breeding Flocks

Primary Breeders

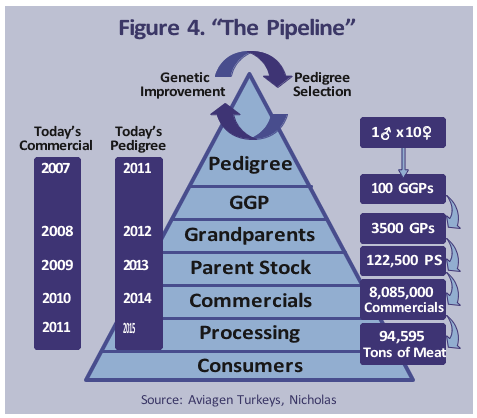

Genetic improvement of commercial turkeys is done using a pyramid system similar to that for broilers and swine. A representative genetic pyramid illustrating production of Aviagen turkey breeders is shown in Figure 4. As many as 5 generations go into producing commercial turkeys. Individual lines are purebred so that the final generation is a three- or four-way cross. It takes about 4 years for pedigree genetics to be realized in the commercial meat birds. To obtain turkeys with the highest production potential, substantial selection pressure is applied to primary breeders. Primary breeders are maintained under the highest level of biosecurity possible because of their value and critical importance in the production pyramid. Each pedigree tom is ultimately responsible for producing over 8 million commercial turkeys and just over 94.5 tons of turkey meat, while each pedigree hen is ultimately responsible for around 800,000 commercial turkeys and nearly 9.5 tons of turkey meat. Primary breeder companies are independent of commercial turkey producers.

Primary breeders select for turkeys that improve production efficiency (growth rate, feed utilization, meat yield and quality), reproductive performance (number of eggs, number of poults, poult cost), and ability to do well in production environments (high livability, low morbidity). During the past few decades, live weights and feed utilization of commercial turkeys have increased approximately 2.3% and 1% per year respectively. Realization of these annual improvements in genetic potential requires meeting the turkey’s nutritional, environmental, and health requirements for optimal production. Attention to growth (body weight control) and skeletal (frame) development, proper light stimulation, and good nutrition are essential for optimal rearing of both breeder hens and toms.

Parent Stock (Commercial or Multiplier Breeders)

Female parent breeding stock is usually supplied by primary breeders to commercial companies as fertile eggs from the hen line while tom parent breeders are provided as day-old poults. One or both grandparent lines are hybrids. When they are crossed to create the parent breeders (also called multiplier breeders), the commercial turkeys will be either 3-way or 4-way hybrids. Eggs supplied by the primary breeders for parent stock are hatched in the most biosecure method available to the company. Sometimes a hatchery separate from where commercial poults are hatched is used, but more commonly, breeder eggs are hatched in the same hatchery by themselves without commercial poults being hatched at the same time. In the hatchery, breeder poults are serviced the same as commercial poults (see 2.3.1). Off-sex poults (males from the female line) are raised as commercial poults, but their productivity is lower. Breeder (“replacement”) hens and toms go to breeder farms where they are raised separately.

Breeder Toms

Replacement tom poults are placed on a tom only (“stud”) farm, in a separate facility on a breeder replacement farm, or in a separate pen in a house that also has replacement hen poults. Ideally, breeders are placed on single-age farms that are isolated from commercial farms and other poultry. Regardless of the exact arrangement, sexes are reared separately. Facilities for breeders are thoroughly cleaned and disinfected prior to arrival of the poults. Except for providing approximately twice the floor space and optimizing biosecurity and management, brooding breeder toms is not significantly different from brooding commercial toms (see 2.4).

Controlling weight and development is essential for producing good breeders. To aid in development of male breeders, starter feed with higher protein (28%) and energy levels is provided for at least 4 weeks. Feed is generally not restricted until candidate breeders are selected at 16-18 weeks of age. This permits identification of the best males based on how well they have grown and developed. Following selection, weights of specific toms are determined weekly and growth is controlled through either qualitative (ad libitum feeding) or quantitative feeding programs (limited feeding). Both programs use low density rations that typically have around 10% protein. However, it is important for toms to continue to gain a recommended amount of weight throughout the production period, and to weigh approximately 50 lbs (22.5 kg) at 30 weeks when semen is first collected. Just over 200 lbs (91 kg) of feed per tom are needed to meet this target. Uniformity also is important; 90% of toms need to be at target weight (average weight ±10%) when semen is first collected. Standard body weights and recommended feeding programs are available online for both Aviagen (Nicholas) and Hybrid commercial turkeys (see Acknowledgements).

From one to 15 weeks of age, breeder toms are given more floor space than commercial toms to promote activity and develop strong legs (4-6 ft2 [0.3-0.6 m2]. They receive 8-10 ft2 [0.7-0.9 m2] from 16 weeks to the end of semen production). After selection, groups of 20-25 toms are placed into pens of at least 250 ft2 [23 m2] in the tom barn. Groups often are divided into the heaviest toms, which are the prime breeders and used most often for insemination, intermediate toms used when additional inseminations are needed, and lighter toms kept in reserve.

Breeder Hens

Breeder replacement hens are brooded and raised in breeder replacement (rearing) houses as single age flocks similar to brooding and growing commercial hens. Biosecurity is high because of their value and critical role in providing fertile eggs for the company. Breeder replacement hens are typically given about twice as much floor space (4-5 ft2) as their commercial counterparts, and are provided an optimal environment, especially as it relates to air quality. Around 17 weeks of age, hens to be used as breeders are selected. In contrast to toms, selection pressure for candidate breeder hens is minimal, generally around 5%. Following selection, they are placed into a light-proof “dark-out” house and exposed to short day lengths (6-8 hrs light [L]:16-18 hrs dark [D]) for at least 12 weeks. At 29 weeks, hens are moved into the laying house where they are photostimulated (minimum 14L:10D @ 100 lux), rapidly mature sexually in response to the increased light, and begin egg production between 31 and 32 weeks of age. Egg production peaks a few weeks later when around 75% of the hens will lay eggs each day. Peak production is followed by a gradual decline throughout the remainder of the production period. Egg production typically lasts for 28 weeks but may be a few weeks shorter or longer depending on how the flock is producing, need for fertile eggs, and economics. Each hen produces between 100 to 120 eggs from which 90 to 100 poults are hatched. Typical overall hatchability is 82 to 84 percent. Hens may be brought into a second egg production cycle (“recycled”) by moving them back to a dark-out house and inducing molting. Recycled hens produce fewer eggs, but eggs are larger resulting in high quality poults. Breeder hens are processed for meat at the end of their egg laying cycle(s).

Management considerations for turkey breeder hens include nutrition, weight management and hen development, vaccination, light control, insemination, broodiness control, and egg production and handling. Desirable outcomes for a turkey breeder flock are uniform egg production that meets or exceeds breed standards, high peak egg production, persistence of egg production (total eggs/hen housed), and high fertility and hatchability, which all contribute to reduced poult cost.

Weight control and development to achieve optimal reproductive performance are more important for breeder replacement hens than toms. Overweight hens are poor breeders, prone to reproductive disorders, produce fewer eggs, more likely to become broody, and more likely to be culled. Determining weekly weights of a representative number of hens beginning at 3 weeks of age is ideal, but critical weight determinations are at 6, 16, and 22 weeks. At least 50 birds should be weighed to get an accurate average weight. The amount and type of feed allocated to the birds is based on the average weight of the flock. Higher protein feed is given to flocks that are lighter than the target, while heavier flocks are moved more quickly onto lower protein rations. Adjustments in growth need to be made gradually; hens must continually gain weight prior to egg production even if they are above the target. Hens are usually switched to a laying ration when they are moved to the laying house, but in some cases, a pre-lay ration that is intermediate between the conditioning ration and laying ration is used for the last few weeks in the dark-out house. The average weight of breeder hens at photostimulation needs to be around 26 lbs (11.8 kg).

Sexual development and initiation of egg production are highly dependent on light exposure including duration, intensity, and wavelength. Replacement hens are naturally photorefractory when they are young, but afterwards become photosensitive to even very low levels of light. If exposed to additional light during dark-out, sexual maturity begins prematurely and hens will be poor breeders. Hen flocks that become sexually mature during the time when it would occur naturally (increasing day length) tend to produce more eggs, even when maintained in a light-controlled environment. Hens receptive to breeding display a characteristic “squatting” behavior that has occasionally been confused with lameness. This should be seen in the majority of the hens after light stimulation. Initial insemination is done at this time. Inseminating the hens too soon can result in vaginitis, peritonitis, impaired reproduction, and death (Gazdzinski and Barnes, 2004). If squatting is seen during dark-out, it indicates a problem with light control. It is critical that neither the duration nor intensity of light is reduced while the hens are in production. Day length can be increased, but should not exceed 18 hours.

Vaccination of breeder hens is done to prevent mortality and maintain egg production and quality. Although not as important in turkeys as it is in broiler chickens, a few vaccines are given to provide maternal immunity to poults (e.g., hemorrhagic enteritis). Another purpose of breeder hen vaccination is to reduce or eliminate vertical disease transmission (e.g., avian encephalomyelitis virus, Salmonella). Vaccination programs vary among companies and geographic region. Inactivated oilemulsion vaccines are given several weeks prior to photostimulation to avoid drops in egg production that occur when they are used while hens are laying. Inactivated vaccines made with aluminum hydroxide can safely be used when the hens are in production. Commercially available vaccines used in turkey breeders are listed in Table 5. Under special circumstances, inactivated autogenous vaccines are prepared and used following strict guidelines. An example of an autogenous vaccine in current use is one that contains Pasteurella multocida, Ornithobacterium rhinotracheale (“ORT”), and Erysipelothrix rhusiopathiae to aid in the prevention of fowl cholera, ORT, and erysipelas respectively. Vaccines for chickens are sometimes used off-label in turkeys and usually have good efficacy. An example of such use is immunizing breeder replacements with herpes virus of turkeys (HVT)-vectored avian paramyxovirus 1 (Newcastle) vaccine. Live mycoplasmal vaccines are not recommended for turkeys, as they are more virulent in turkeys than they are in layer chickens.

Table 5. Vaccines Used in Turkey Breeder Hens. |

|||

Vaccine |

Type |

Administration |

Comments |

Avian paramyxovirus 1 (Newcastle) |

Live. Strains C2, B1, La Sota, N-79, N-63, Clone 30, etc. |

Water, spray, intranasal, eye-drop. |

Vaccines made for chickens typically include infectious bronchitis virus (IBV). There is no evidence that IBV will infect turkeys. |

Avian paramyxovirus 1 (Newcastle) |

Inactivated. |

Injection. |

Often combined with other vaccines (e.g., PMV3, Influenza). Used in breeders to provide high immunity of long duration. |

Paramyxovirus 3 |

Inactivated. |

Injection. |

Often combined with other inactivated virus vaccines. |

Influenza |

Inactivated. H1N1, H3N2 swine strains. |

Injection. |

Often combined with other inactivated virus vaccines. |

Hemorrhagic enteritis |

Live. Avirulent, pheasant origin. |

Water. |

Splenic homegenate vaccines should not be used in breeders. |

Avian encephalomyelitis |

Live. Strain 1143. |

Wing-web, water, spray. |

Often combined with pox and given via wing web inoculation. |

Pox |

Live. Fowl, turkey, pigeon types. |

Wing-web, feather follicle. |

Often combined with AE and given via wing web inoculation. |

Turkey rhinotracheitis |

Live, inactivated. Avian metapneumovirus. |

Water, eye-drop, intranasal, coarse spray, injection. |

Used where TRT is endemic. |

Erysipelas |

Inactivated. |

Injection. |

Often combined with other bacterial antigens. |

Fowl cholera |

Live, inactivated. Strains M-9, PM-1, CU. |

Water, wing-web, SQ or IM injection (inactivated). |

One to 2 “priming” vaccinations given in water with low virulent strains followed by injection with higher virulent strain. |

Salmonella |

Inactivated. |

SQ injection. |

Used to reduce Salmonella contamination of eggs and vertical transmission. |

Colibacillosis |

Live, inactivated. |

Spray, SQ injection (inactivated). |

Intramuscular vaccination with inactivated vaccine can produce severe granulomatous myositis. |

Egg production commences 2 to 3 weeks after hens are placed into the laying house and exposed to increased light. Eggs from young breeders are smaller and produce smaller poults that are more difficult to start when placed on a brooder farm. It is important during the early laying period to train the hens to use the nest for laying. Eggs laid outside the nest (“floor eggs”) are more likely to be contaminated and either not hatch or explode when incubated due to growth of gas-forming bacteria that penetrate the egg shell. A nest box needs to be provided for every 4 to 6 hens. Semi-trap nest boxes prevent more than one hen from entering the nest box. Both manual and automatic nest boxes are used. To obtain the most sanitary eggs, bedding in nest boxes needs to be kept clean, eggs collected frequently, and hens not permitted to remain on the nest. Abnormally small, large (double-yolk), misshapen, cracked, or excessively dirty eggs are removed and discarded. In contrast to broiler hatching eggs, turkey hatching eggs are often washed in a warm (110-120°F, 43-49°C) detergent-sanitizer solution. However, egg washing is not a substitute for management practices that result in production of clean eggs, or a salvage procedure for excessively dirty eggs. After drying, eggs are identified, dated, packed, and placed into an egg cooler where they are kept at 55-65°F (13-18°C) until they are picked up, usually twice a week, and moved to the hatchery. Eggs may be kept at slightly warmer or cooler temperatures if they are going to be stored for shorter or longer periods respectively. Optimal relative humidity is 60-80%. Sweating of eggs as they are transported to the hatchery can be a problem if ambient temperature and humidity are high. Moisture that develops on the eggs from sweating favors bacterial multiplication and wicking of bacteria into the egg through pores in the shell.

Turkey breeder hens retain some of their natural instinct to brood a clutch of a dozen or so eggs after they have been laid. Prevention of broodiness is necessary to obtain maximum egg production. Broody hens may be difficult to recognize but usually they want to stay in the nest box, go out of production, or are more aggressive at protecting the nest. Some hens do not show any signs. Once a hen becomes broody, her reproductive cycle has ended until after she molts. Several management practices are used to prevent broodiness including providing a house environment that is not conducive to nest building, making sure the hen does not stay in the nest box longer than necessary, keeping hens out of nest boxes overnight, providing uniform lighting without dark areas, frequently collecting eggs including picking up floor eggs, checking for hens that return to a nest box shortly after having laid an egg, and marking hens showing signs of becoming broody. Suspect broody hens are transferred to broody pens where their normal environment and routine are altered, or they are moved among pens in the same house. When a hen resumes squatting, she is not broody and can be returned to the flock. While controlling broodiness is important, it is equally important not to be overly aggressive and interrupt production of normal hens.

Artificial Insemination

A common belief is that commercial turkeys are incapable of natural breeding due to their large breast size. This is not entirely correct. They can mate naturally, but the process is not efficient enough to meet the needs of commercial production. Artificial insemination is used to improve and maintain a high level of fertility in commercial turkey flocks. Toms are large birds and expensive to maintain, which makes maximum use of semen from each tom essential to minimize poult costs. Typically, a single reproductively sound male is sufficient for inseminating between 16 and 22 hens. Artificial insemination has also been useful for controlling venereal diseases, especially mycoplasmosis, by preventing mating with infected hens,

Semen is collected from tom turkeys by manual ejaculation (“milking”), pooled, chilled to 1-3°C (33-37°F), and used as quickly as possible, ideally within 30 minutes. Good quality semen is thick, creamy, and white whereas semen that is thin, watery, and yellow is poor quality and should not be used. Usually between 0.3 and 0.6 ml of semen is produced per ejaculation that contains 2 to 6 billion spermatozoa. Semen can be collected twice a week without affecting its quality. Even if semen is not needed and will be discarded, toms should be ejaculated at least weekly to maintain production.

Fertility depends on number of spermatozoa inseminated. Semen is typically diluted 1:1 with semen extender to contain between 300 and 400 million spermatozoa per insemination depending on the age of the breeder hens to be inseminated. Semen extenders are added to pooled semen to increase semen volume so that more hens can be inseminated, but they do not affect the lifespan of the spermatozoa. Semen is deposited by gently blowing it through a pipette inserted deeply into the female’s everted vagina. By placing semen directly into the vagina, spermatozoa are deposited close to sperm host (“sperm storage”) glands where they can survive for up to 3 weeks or longer. However, to insure continual high fertility, insemination of hens is done multiple times during the first few weeks, followed by weekly inseminations thereafter. Additional inseminations and inseminating hens outside of the daily peak of egg production are also done.

Insemination requires precision and coordination to be done effectively and efficiently. Details are beyond the scope of this chapter but can be found in technical information available from Aviagen Turkeys (http:// en.aviagen.com/turkeys/), Hybrid Turkeys (http://www.hybridturkeys.com/), and The Midwest Poultry Federation (Bakst and Long, 2010).

Reference: "USDA APHIS | FAD Prep Industry Manuals". Aphis.Usda.Gov. 2013. https://www.aphis.usda.gov/aph...

The manual was produced by the Center for Food Security and Public Health, Iowa State University of Science and Technology, College of Veterinary Medicine, in collaboration with the USDA Animal and Plant Health Inspection Service through a cooperative agreement.