US Poultry Industry Manual - Sources of breaking eggs

Learn more about sources of breaking eggsPart of Series:

< Previous Article in Series Next Article in Series >

Editor's Note: The following content is an excerpt from Poultry Industry Manual: The Foreign Animal Disease Preparedness and Response Plan (FAD PReP)/National Animal Health Emergency Management System (NAHEMS) Guidelines which is designed to provide a framework for dealing with an animal health emergency in the United States. Additional content from the manual will be provided as an article series.

Sources of breaking eggs

Egg breaking operations process approximately 30% of eggs produced in the United States. Breaking facilities can be located on the farm where the eggs are produced (in-line and on-site) or at some other off-site location. Egg breaking operations may obtain eggs from company-owned farms or purchase eggs from other egg producers who have surplus eggs. All eggs produced on company-owned farms are sent to breaking and high quality eggs from these farms result in high quality finished products. Eggs purchased from other egg producers have traditionally consisted of undersized, oversized, cracked, dirty, or stained eggs.

In-Line Eggs

In-line operations may produce washed, sanitized, and graded shell eggs for retail or food service customers and concurrently send eggs to a breaking plant. Surplus, small, and under-grade eggs may be diverted to a company-owned, on-site breaking facility or transported to a stand-alone regional breaking plant at another location. Eggs are collected from individual barns and carried to on-site breaking plants via a collection of belts and conveyors. Large in-line egg farms with breaking plants may have up to 4 million laying hens on the premises. Some in-line operations have equipment arranged so that shell eggs from other farms can be side loaded and merged with eggs produced on their own farm. In contrast, other in-line facilities break only eggs produced on that farm.

Off-line (Nest Run) Eggs

Nest run eggs can be delivered to either an in-line egg operation with a breaking plant or taken to a stand-alone, centrally located egg breaking plant that receives shell eggs for breaking from multiple farms. Nest run eggs are usually held in bulk until they are broken.

EGG BREAKING MACHINES AND PRODUCTS

Steps in egg breaking

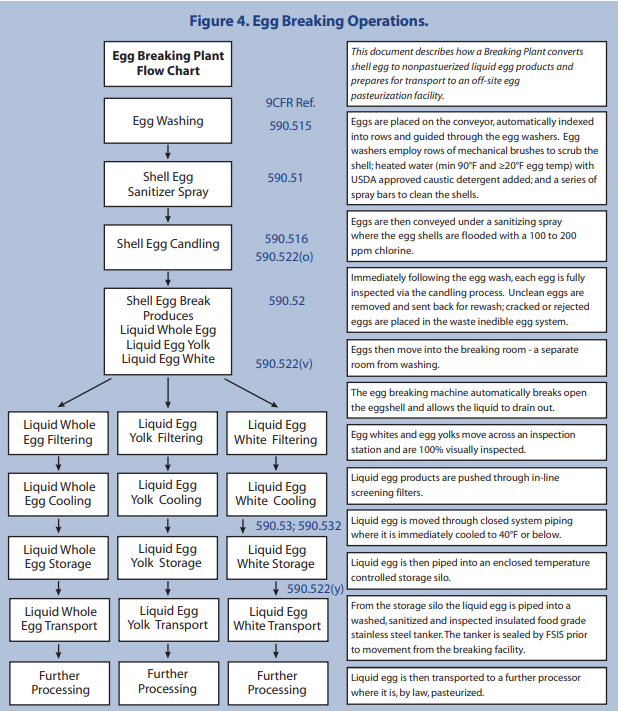

The primary steps associated with egg breaking are 1) washing the shell eggs; 2) sanitizing external shell surfaces; 3) candling/inspecting the shell eggs; 4) breaking the shell and separating the contents; 5) screening and chilling liquid eggs; and 6) storage and transport for further processing.

Breaking machines

Breaking machines are located in a separate room from the transfer and washing processes. Breaking machines are mechanical devices designed to open individual shell eggs in a series of operations that allow control and inspection of each individual egg. Individual eggs are picked up by the machine, the shell is broken, and contents of each egg are secured in an individual “cup” for inspection. High speed machines have the capacity to break up to 140,000 eggs per hour.

Non-pasteurized liquid egg products

Machines may be set up to produce liquid whole eggs (natural proportions of yolk and white), liquid yolk, and/ or liquid egg whites. Production of liquid yolk and liquid white is known as “separation”. Liquid egg is collected as separate streams of whole egg, whites, or yolk and pumped through screens that remove shell fragments and break down native structures of the yolk membrane and egg white. The screening process results in homogeneous fluids that are transferred via stainless steel-enclosed pipes through a heat exchanger where the temperature of liquid egg components is reduced to ≤ 40°F prior to accumulation in chilled storage tanks. Non-pasteurized liquid egg (NPLE) is held in chilled and agitated storage tanks until transfer for further processing at the breaking location or at an off-site facility. Approximately 425,000 eggs are required to fill a single 50,000-pound liquid egg tanker truck. Regardless of the plant location, all shell eggs are converted to liquid egg for further processing as depicted in Figure 4.

Non-pasteurized liquid egg products movement

Non-pasteurized liquid egg products are transported under Food Safety and Inspection Service (FSIS) seal in large insulated tanker trucks or in smaller containers such as “totes” or plastic “lined barrels.” Transfers to tankers, and/or other containers, are accomplished using sanitary enclosed transfer lines and pumps. FSIS inspectors inspect the condition of the tanker or containers prior to loading NPLE, monitor the transfer of NPLE to transport tankers or containers, provide documentation that will accompany the NPLE in transport, and seal the tanker or transport vehicle. At the receiving destination, FSIS inspectors are required to receive the NPLE, break the seal, and document the condition of the contents when received. Tankers are offloaded via flexible lines that connect the tank truck to pumps and stainless steel receiving lines and storage tanks. Totes are generally emptied by attaching a line with a pump to transfer the liquid contents to enclosed lines. Product in barrels may be emptied via pumps or barrel-dumps, and the NPLE is then handled via enclosed process lines.

Pasteurized liquid egg products movement

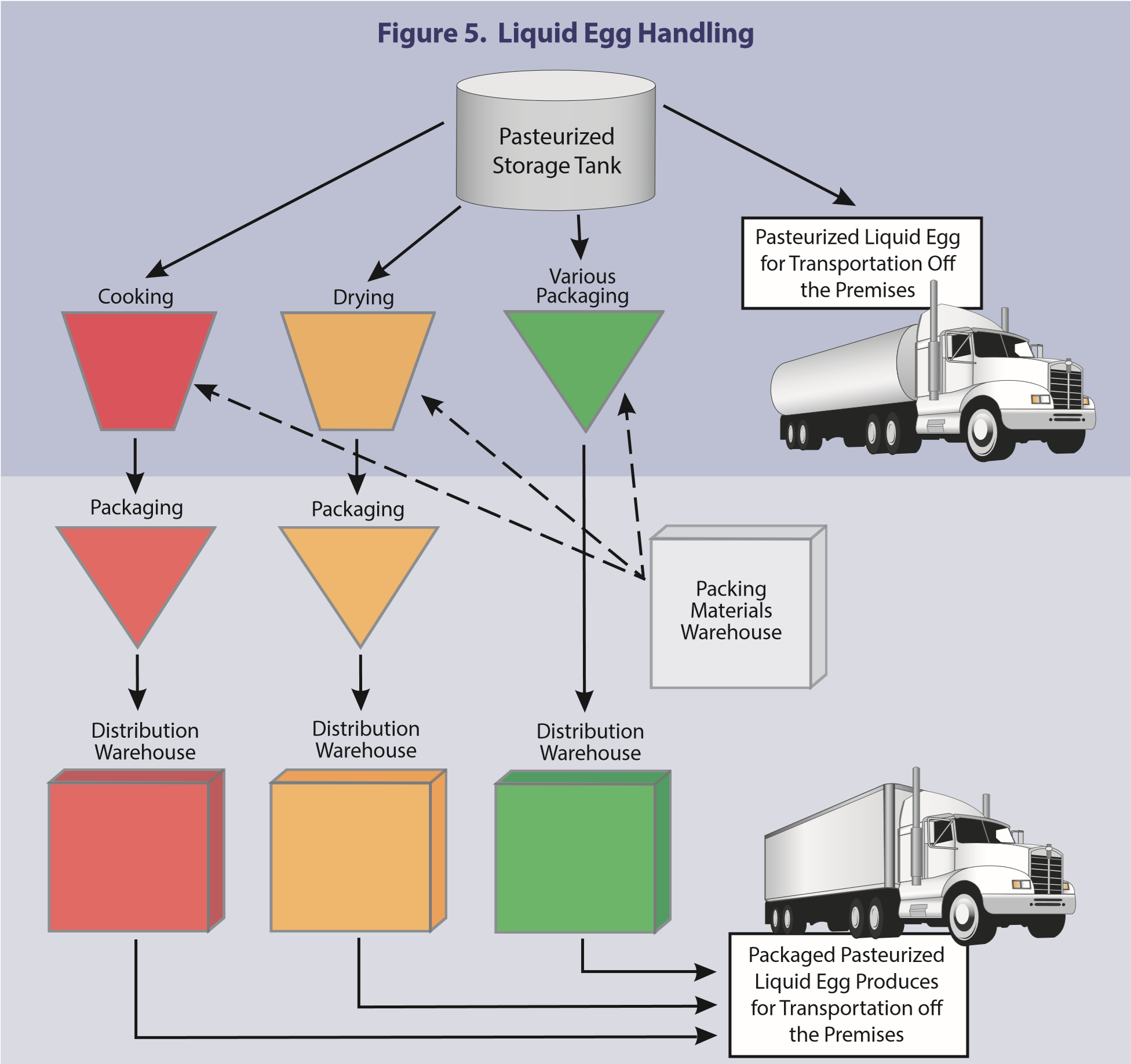

Pasteurization of liquid eggs is required by law and may occur at an in-line or off-line breaking plant. Pasteurized liquid egg may be moved from the pasteurized storage tank at an in-line breaking plant by pumping it directly into large tanker trucks and transported off the premises for further processing at a different location. Alternatively, pasteurized liquid eggs at a stand-alone centrally located egg breaking plant can be moved through internal pipes for further on-premises processing such as cooking, drying, and packaging. Pasteurized liquid egg products from stand-alone plants are moved to appropriate distribution warehouses to be transported to customers at a later time. The journey of liquid egg product after pasteurization until it is put on conveyance trucks to be transported off the premises is shown in Figure 5.

Reference: "USDA APHIS | FAD Prep Industry Manuals". Aphis.Usda.Gov. 2013. https://www.aphis.usda.gov/aph...

The manual was produced by the Center for Food Security and Public Health, Iowa State University of Science and Technology, College of Veterinary Medicine, in collaboration with the USDA Animal and Plant Health Inspection Service through a cooperative agreement.