Is your feed supply making your poultry operation vulnerable to disease?

Disease-causing pathogens have a variety of paths from which they can enter the live production process.Part of Series:

Next Article in Series >

Pathogenic microbes, however, present a significant challenge for producers. Avian Influenza, Newcastle disease and infectious laryngotracheitis can cause significant economic losses and in some cases the loss of the entire flock, whereas other pathogens, like Salmonella and E. coli, are zoonotic and present a risk to human health.

Pathogens have a variety of paths from which they can enter live production. Mechanical vectors such as water sources, rodents, and insects, present a risk within farms, to individual birds and houses, while fomites such as feed, people and vehicles risk the biosecurity of entire complexes and farming operations.

Industry professionals recognize the value of a comprehensive biosecurity programs and are learning from the fast-growing body of new research and analysis of pathogen risk in live production and processing.

“Biosecurity establishes a barrier between the outer world and the animals on the farm, starting with a physical barrier,” said Enrique Montiel, DVM and Director of Nutrition and Live Production at Anitox. “Different countries have different guidelines, but the principle is the same.”

Beyond establishing a physical barrier, disease prevention protocols are typically defined within the operation. For example:

- vaccinating the flock to prevent disease

- disinfecting water systems

- establishing well-ventilated buildings

- replacing litter periodically

- disinfecting the facility between flocks

- sanitizing feed

Sometimes the missing link or hole in a biosecurity plan pathogen control within feed and feed ingredients. Feed plays a role by introducing pathogens two different ways:

- one of the feed ingredients itself is contaminated, or a finished product in the feed that was originally of acceptable quality gets infected during the handling process

- feed gets infected through contamination by other fomites or vectors either on the farm or coming onto the farm and acts as a vehicle for disease transmission

Research results from historical disease outbreaks has prompted recognition for feed as a viral fomite.

“Five years ago, Dr. Haroldo Toro at Auburn University College of Veterinary Medicine published a study looking at feed sanitizer efficacy against Avian Influenza in chicken feed,” stated Dr. Montiel. “Both feed sanitizers tested, Termin-8 and Finio, developed by Anitox, effectively inactivated the virus in feed. Two years later, Dr. Scott Dee and the team at Pipestone Veterinary Services looked at viral survival in feed ingredients by means of a transboundary shipping model. Findings in this study suggest virus survival occurs in feed as well as feed ingredients. However, some ingredient types and feed matrices are better able to support survival than others.”

Numerous studies over the years have established feed as a fomite for organisms like Salmonella, E. coli and Clostridia.

“A study published by Dr. Nikki Shariat at the University of Georgia’s Poultry Diagnostic and Research Center examined nearly 400 feed samples from 135 different feed mills in the US. Using a technique originating from the world of human medicine – CRISPR-typing – Dr. Shariat was able to identify multiple serotypes of Salmonella in feed samples. CRISPR data could better the understanding of the prevalence of contaminants found in the various stages of poultry production from feed to processing,” noted Dr. Montiel. “Recognizing the conditions where different types of bacteria grow and survive throughout production helps producers recognize where mitigation strategies are most impactful.”

Consequences of pathogens entering production facilities

While some pathogens will cause clinical disease symptoms attracting the attention of farmers and veterinarians, other may cause subclinical symptoms that go unnoticed, lowering bird efficiency and creating a flock that can never reach its genetic potential.

“All farmers have to deal with some level of pathogens at the farm, and there is always an economic impact due to this exposure to pathogens,” said Dr. Montiel. “It’s important to proactively monitor the flock and stay on top of any changes in feed or water intake, changes in behavior and stress levels of the flock along with regular diagnostic testing of animals to ensure new pathogens aren’t showing up.”

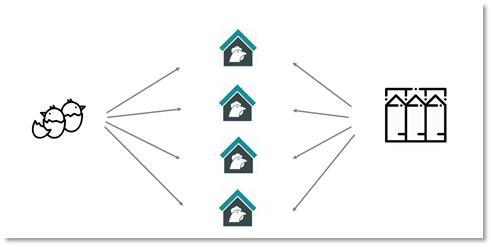

As a fomite, feed can have a significant impact because it can be a route of contamination. Many operations are fed with automatic feeders that will take the feed from one barn to another to another. Feed then becomes a vehicle, spreading the pathogen throughout the entire flock. Thus, efforts to sanitize feed will be important for disease prevention and control.

“Different farms have different needs and disease challenges throughout the production process. However, if you look at the multiple factors that impact the poultry business, feed remains one of the fundamental elements of poultry production,” he said. “Pathogen-contaminated feed has huge consequences because it can potentially affect all of your houses and all of your farms. One of the principles of how disease occurs is that it starts in one house, in one flock, and then disseminates to the rest. When you see a problem that is evenly widespread simultaneously across the whole operation, you have to suspect that it's the feed, because it's being spread systemically.”

There are several ways to sanitize feed and use the treatment as a biosecurity tool for disease prevention. One example is to source high quality feed ingredients to assemble your final feed and have those ingredients sanitized at the source, or after they arrive at the feed mill. Disinfection can be a product that is applied to the ingredients, or it may be a physical element like heat. Another option is to sanitize the finished feed after it is prepared.

“The biggest difference between using any kind of physical element versus a sanitizer is that a feed sanitizer will provide protection against recontamination as feed is transported, stored and fed to your animals,” he noted. “Whereas a physical treatment like heat or irradiation is a spot treatment – it only cleans it at that moment in time, but the feed can be re-contaminated before it reaches the animal.”

Producers wanting to take effective action to protect their flocks against pathogen transmission via feed can get more information at www.anitox.com/poultrysite.