Sustainable practices: learn how to recycle water from your poultry manure

Making wasterwater use a realityAn increasing population, changes in consumption habits and climate change are increasing the competition for freshwater resources along with many other factors. Exploring ways to improve water use and finding ways to extract water from our current food and livestock systems is especially important in tackling our global water challenges.

As part of sustainable development, farmers will have to adopt alternative resources that balance the environment, economy and society. Wastewater reuse represents an opportunity for this challenge as it can alleviate the stress on scarce water resources and contribute to circular economies.

Water consumption by livestock production differs widely between types of animals, regions and production systems and has varied applications such as drinking water for animals, disinfection, cleaning and is often used in crop irrigation usually seen as consumable. The water will eventually get absorbed by the bedding materials, turning into manure after saturation that very often becomes a problem. The solution to this challenge typically involves transport to landfills or spreading on agricultural fields.

Making wastewater reuse a reality

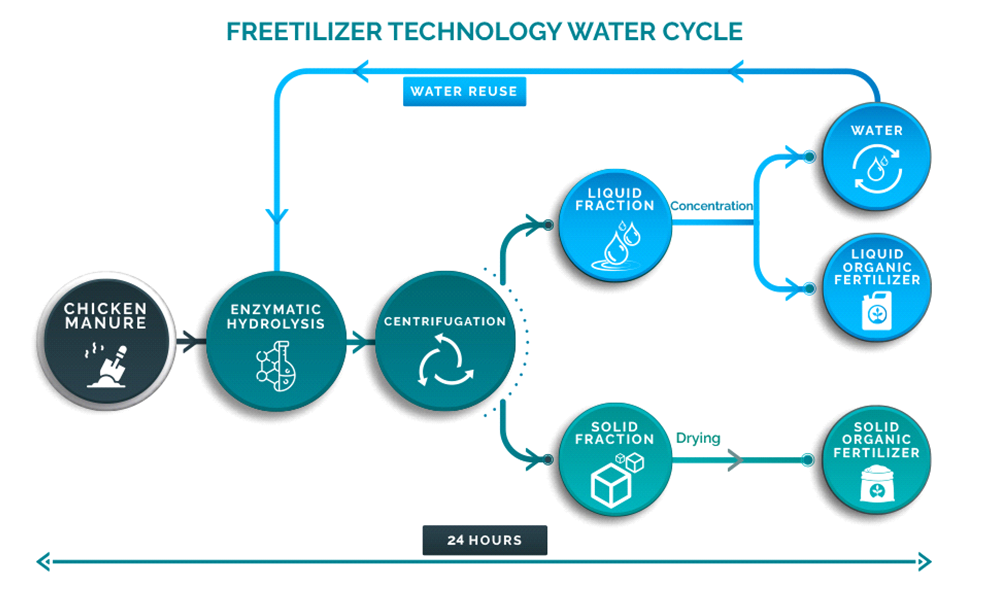

Freetilizer is an innovative technology with a pending patent, based on a hydrolysis process that applies specific enzymes in a reactor with controlled agitation, pH and temperature, that creates new value for organic waste transforming it into organic fertilizers in less than 24 hours. The application of a separation process combined with Freetilizer technology presents excellent results for the valorisation, or increasing the value, of poultry manure and the reuse of wastewater.

How freetilizer works

With Freetilizer technology, you can separate poultry manure into a solid and liquid fraction, drawing value from both fractions and simultaneously representing an inexpensive treatment option. The liquid fraction becomes less concentrated in suspended particles, whereas the solid fraction, retains most of the organic nutrients. The procedure ends with an efficient drying step for the solid fraction, using a vacuum drying process at lower temperatures which guarantees nutrient quality preservation and results in the formation of a stable and nutrient-rich product.

Therefore, the dried solid fraction can be more efficiently transported over longer distances for crop use in arable areas. The liquid fraction can be concentrated efficiently using the vacuum drying system until it reaches a desired nutrient composition that might be used directly at the farm or distributed for commercial purposes. The evaporated water is condensed, stored and can be reused.

The water recycled by the Freetilizer process not only allows it to be valued as an organic fertilizer, but it can also be used in other animal production processes. As such, it offers unprecedented flexibility and opens many opportunities for its use, while saving a precious resource, reducing costs and respecting nature.

At Pipemasters we believe that we must give back to the land what we have taken from it. And that's exactly why, time and effort was invested in the development of a solution that, as far as we know, is unlike any other technology on the market for the recovery of organic waste and the valorization of water.